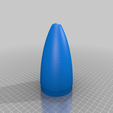

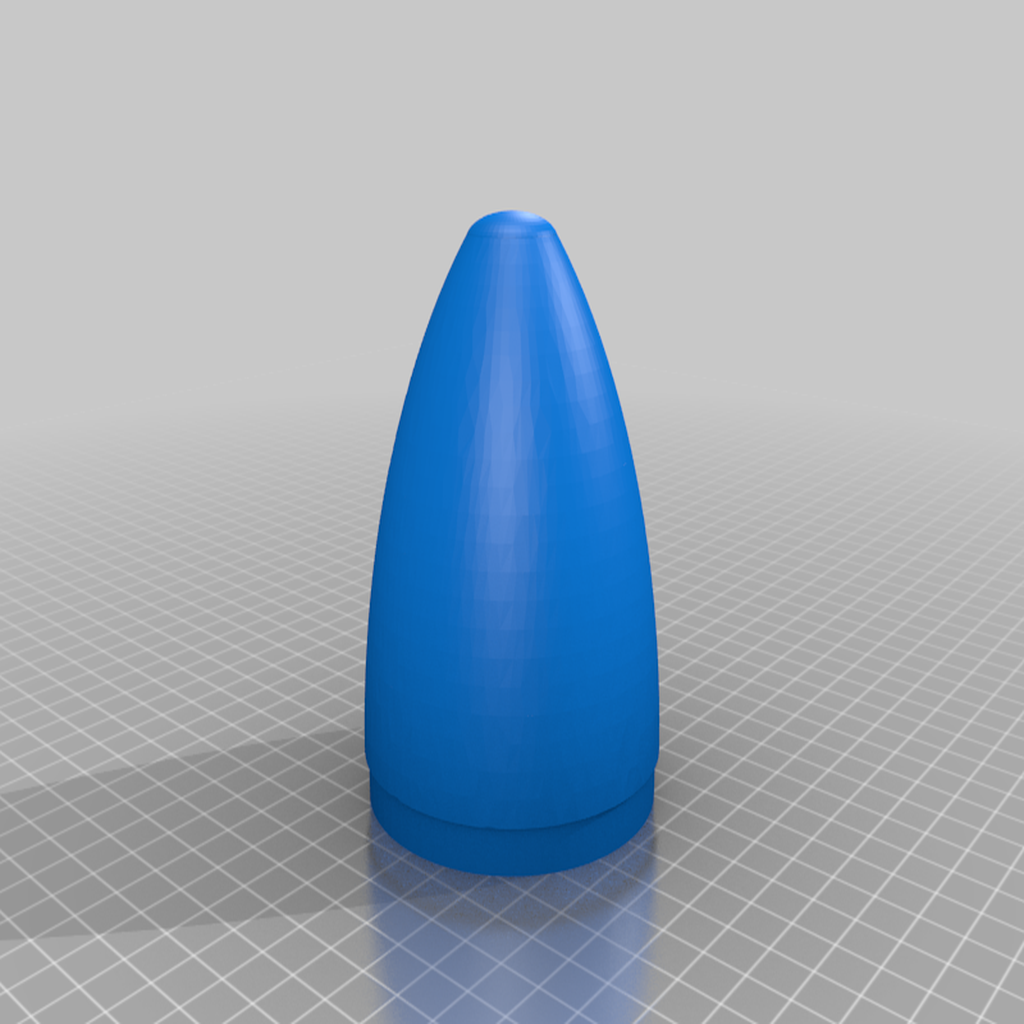

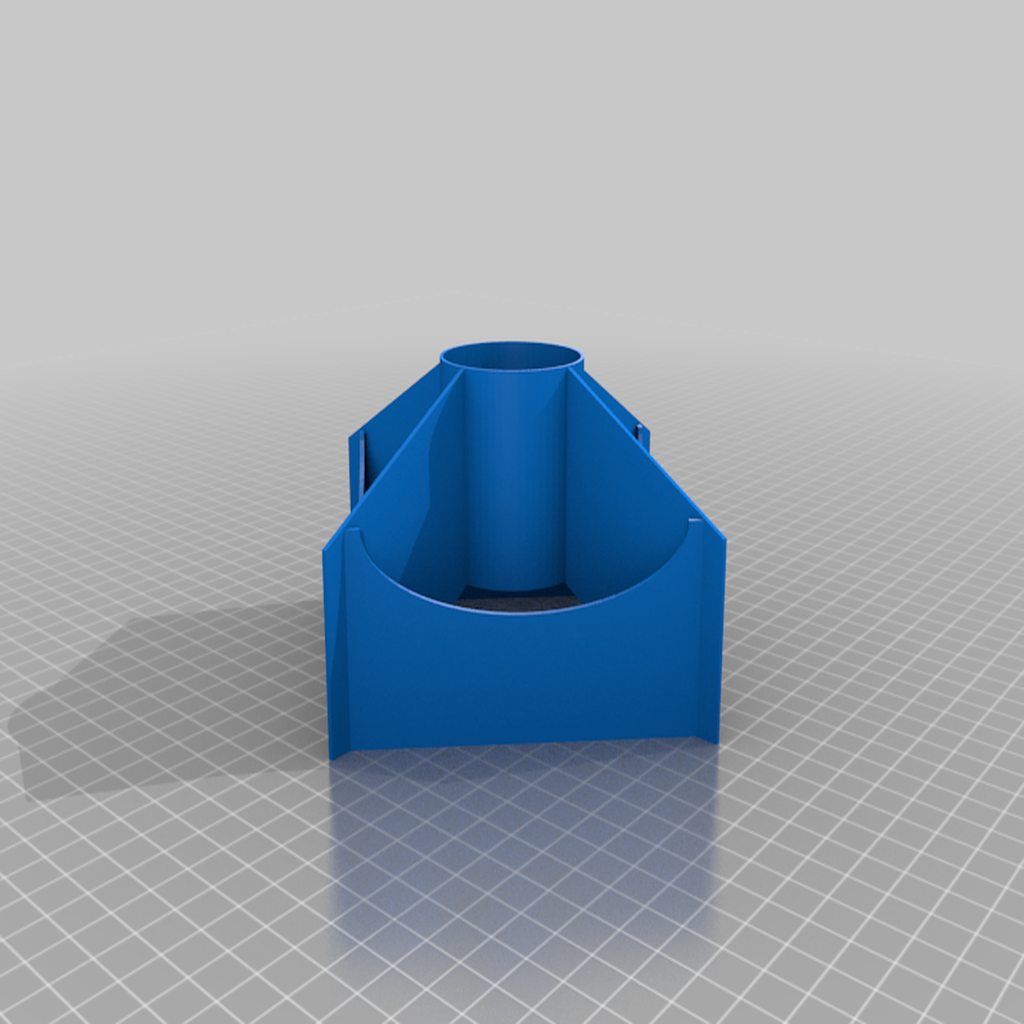

This is an update to my original Rear Eject Bomb Rocket: https://www.thingiverse.com/thing:3138410

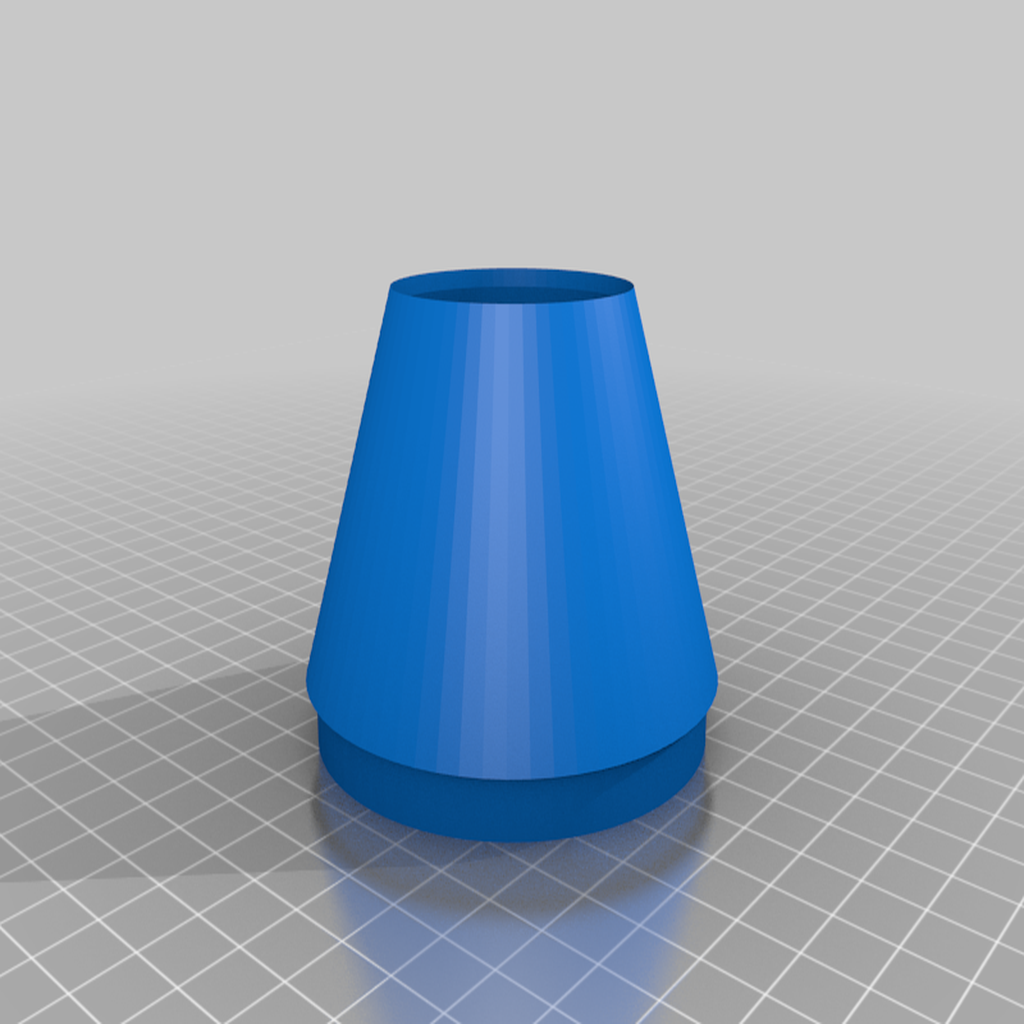

Instead of using an obscure paper towel tube, however, it uses a standard Estes BT-60 tube.

To build this rocket you will need:

A standard Pringles Can

290 mm or so of BT-60 body tube.

240 mm or so of BT-50 body tube (for the motor pod)

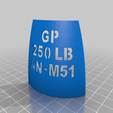

A 15" Chute

A 9" Chute

Kevlar Line

Elastic for a shock cord

A 3d Printer, of course and filament to print the parts

Paint to preference

Decal inkjet paper if you choose to print the decals from the original design.

This rocket is designed to use Estes engines up to the E size (95mm) or Aerotech engines up to F size. Mind you I don't know if it will survive motors that size, but it should.

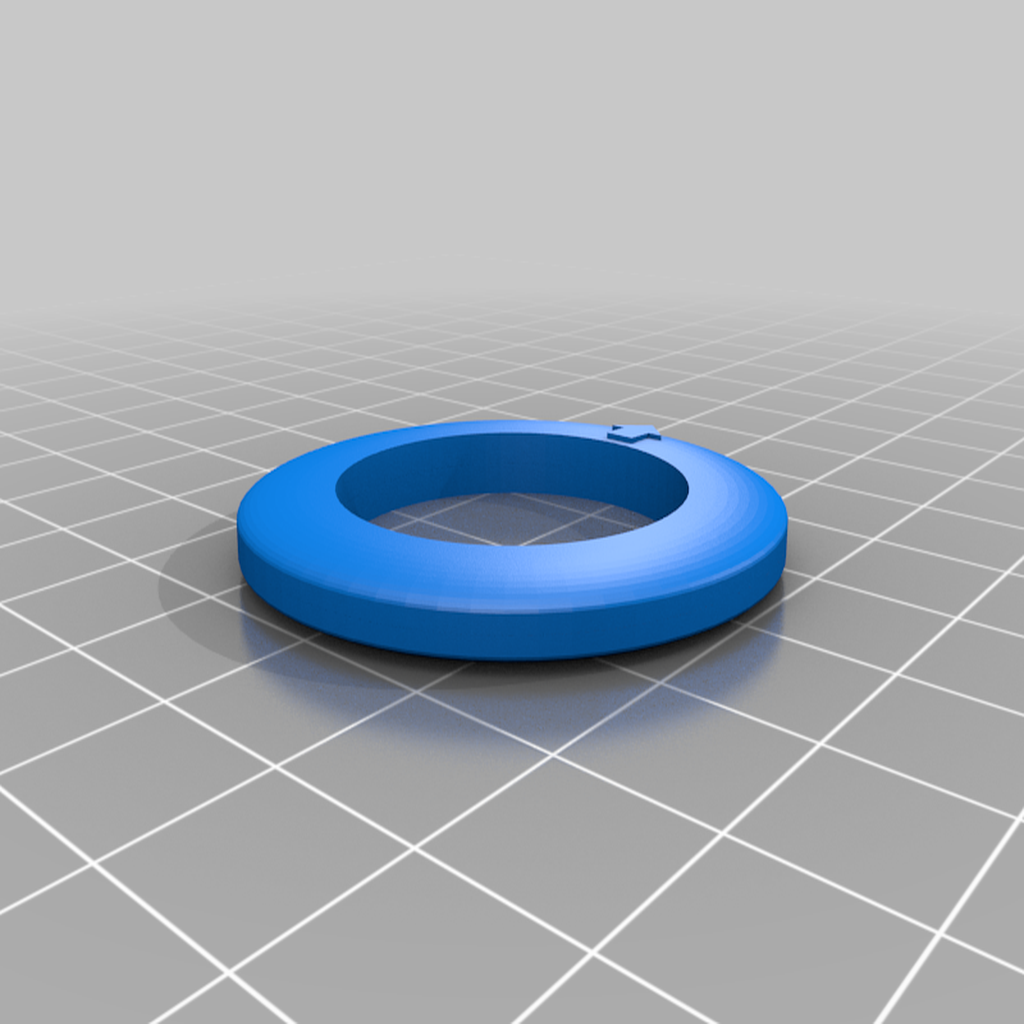

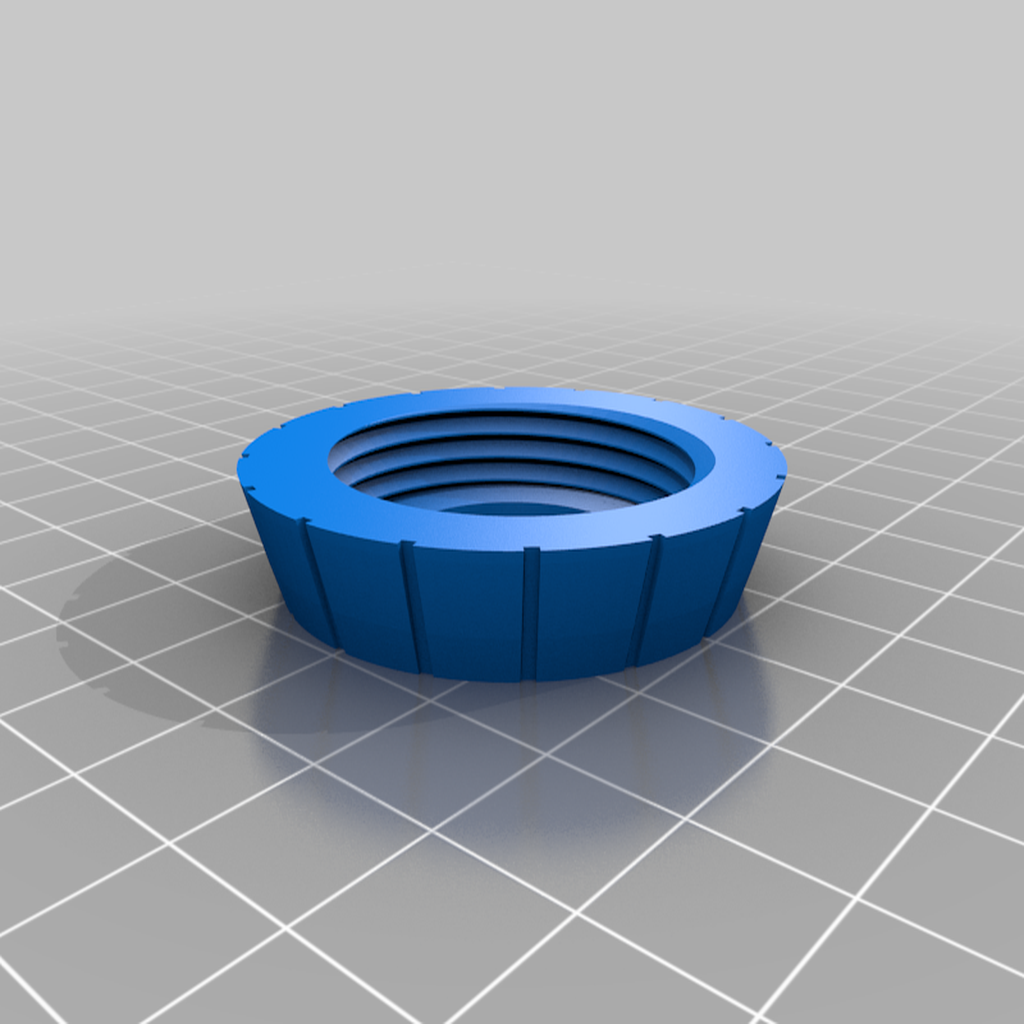

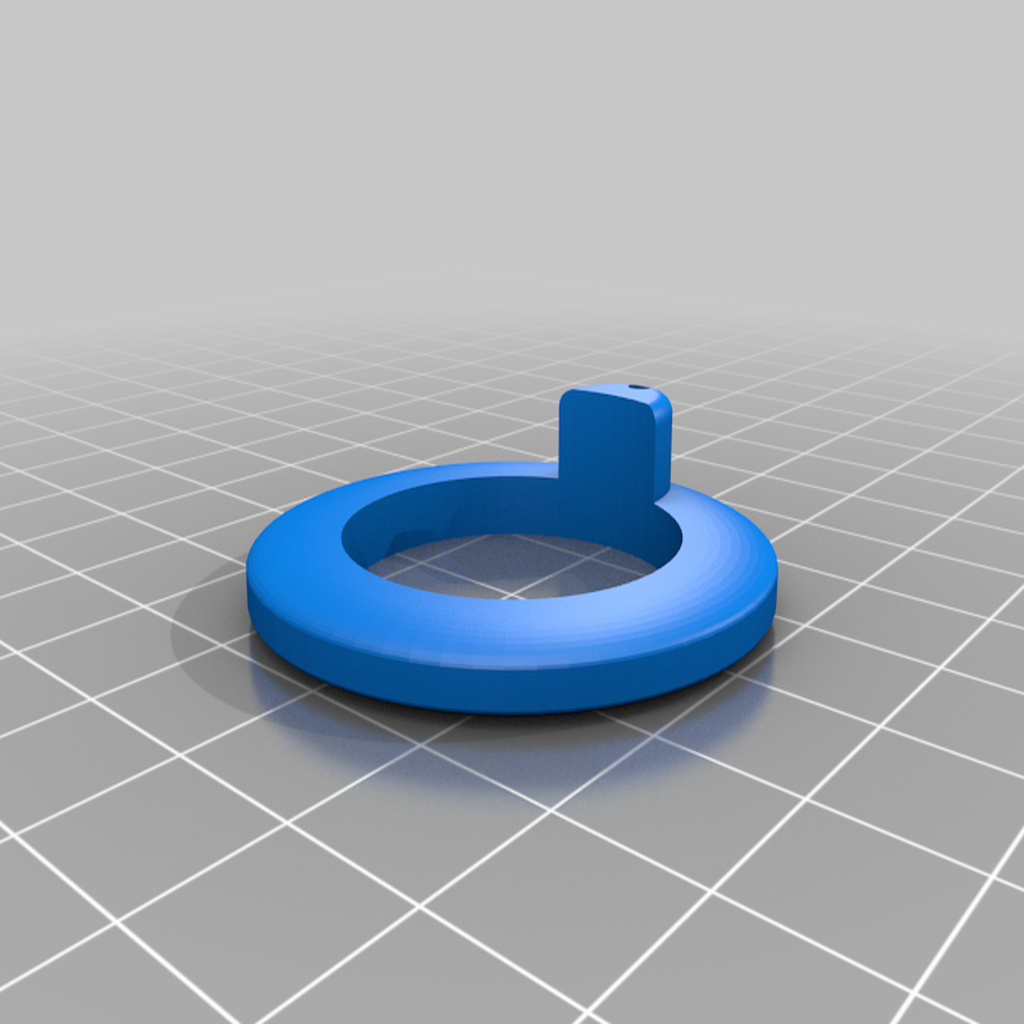

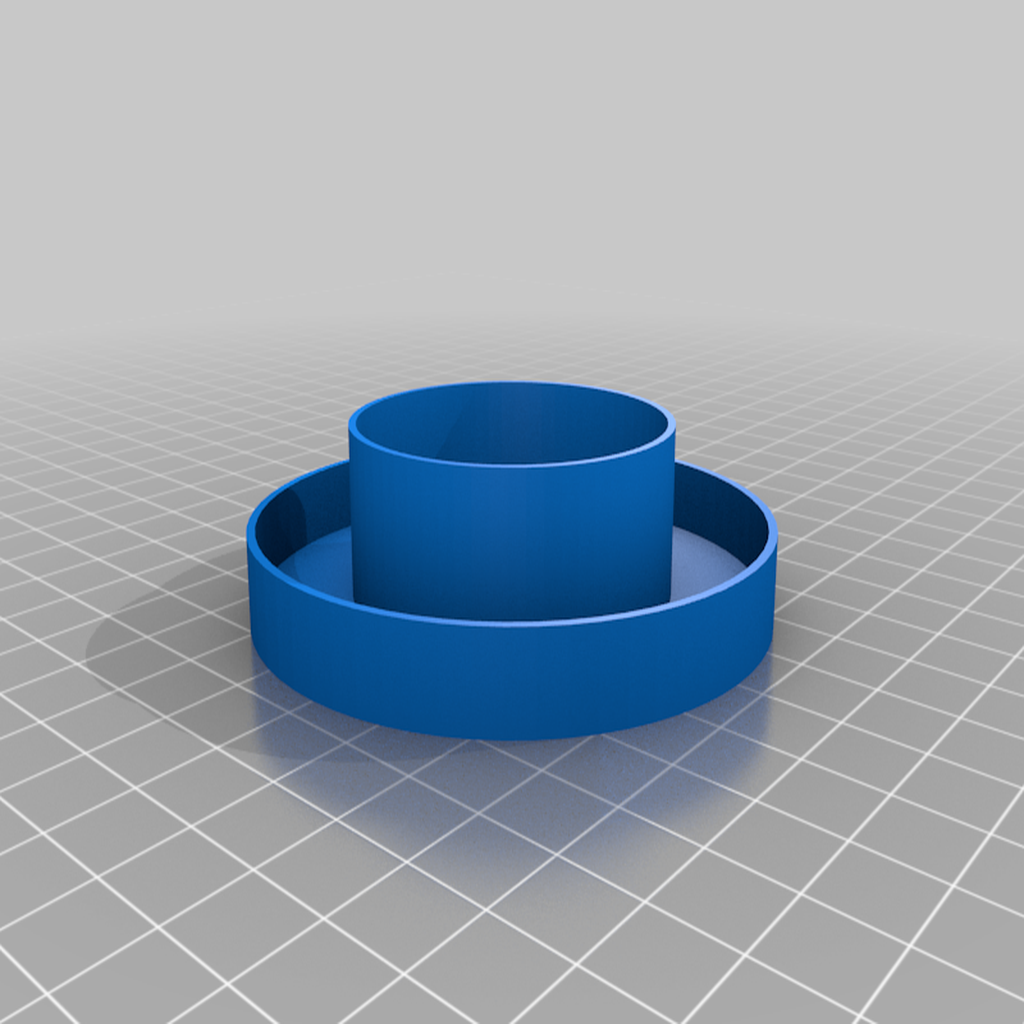

The "ScrewtopInner" and "ScrewtopOuter" parts are glued to the inner nosecone bottom and top of the Centering RIng to allow you to unscrew the nose cone as opposed to gluing it in place. These parts are OPTIONAL, but I added them because I like to put an altimeter in my rockets. The "Inner" part has four holes at an angle. Once you've glued it in, drill through these holes to create the vent the altimeter will need.

Build notes:

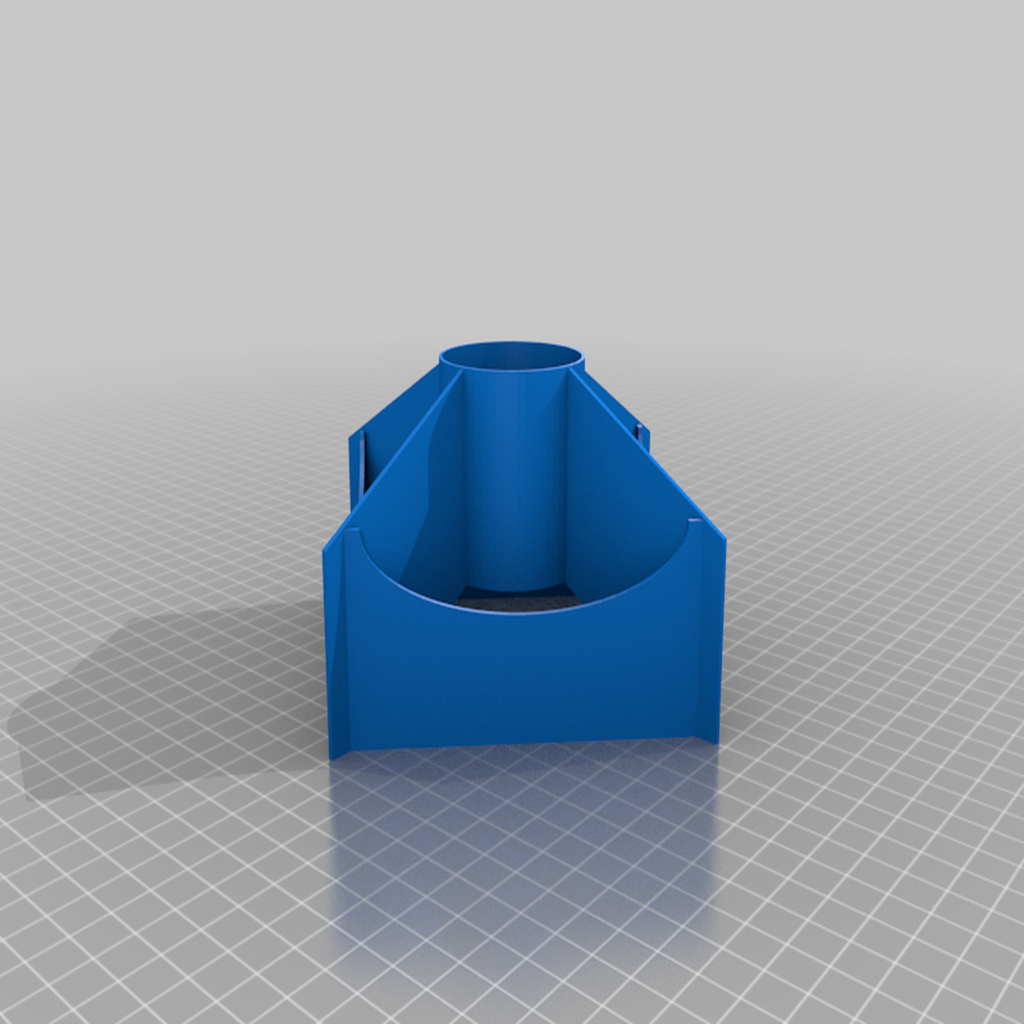

1) The parachute attaches to a screw eye threaded through the center of the "Centering Ring" part, which goes on top of the BT-60 tube. Tie kevlar line to this and run it through the tube. This line WILL be exposed to exhaust gasses. I also used a piece of nomex cloth against the inside of this centering ring to protect the plastic.

2) The kevlar line runs between the BT-60 tube and the "motor top" ring. It's important that the entire motor tube assembly slide easily in and out of the paper towel tube, but not be so loose as to fall out when assembled. To this end, this part has a notch for the kevlar line. Depending on the line you use you may have to widen this notch. The part has an arrow on it you can paint (or use a marker on) to highlight where the line is to go.

3) I only used enough Kevlar to get beyond the bottom of the rocket, then tied elastic to it. This shortens the amount of line you should need. The parachute for the bomb part of the rocket attaches to the bottom of the elastic cord.

4) There is a centering ring for the middle of the motor pod. This ring has a raised nub for screwing in a screw eye that the parachute for the pod can connect to. This nub should be facing the BOTTOM of the rocket. The intent is for the "Bomb" chute and shock cord to be isolated in the upper part of the motor bay by this ring and the pod chute to be isolated in the lower part of the motor bay. ALL RINGS SHOULD BE SANDED TO ALLOW THE MOTOR TUBE TO SLIDE EASILY OUT OF THE MOTOR BAY, but not so loose that it falls out.

5) I used an 15" chute for the bomb and a 9" chute for the motor pod.

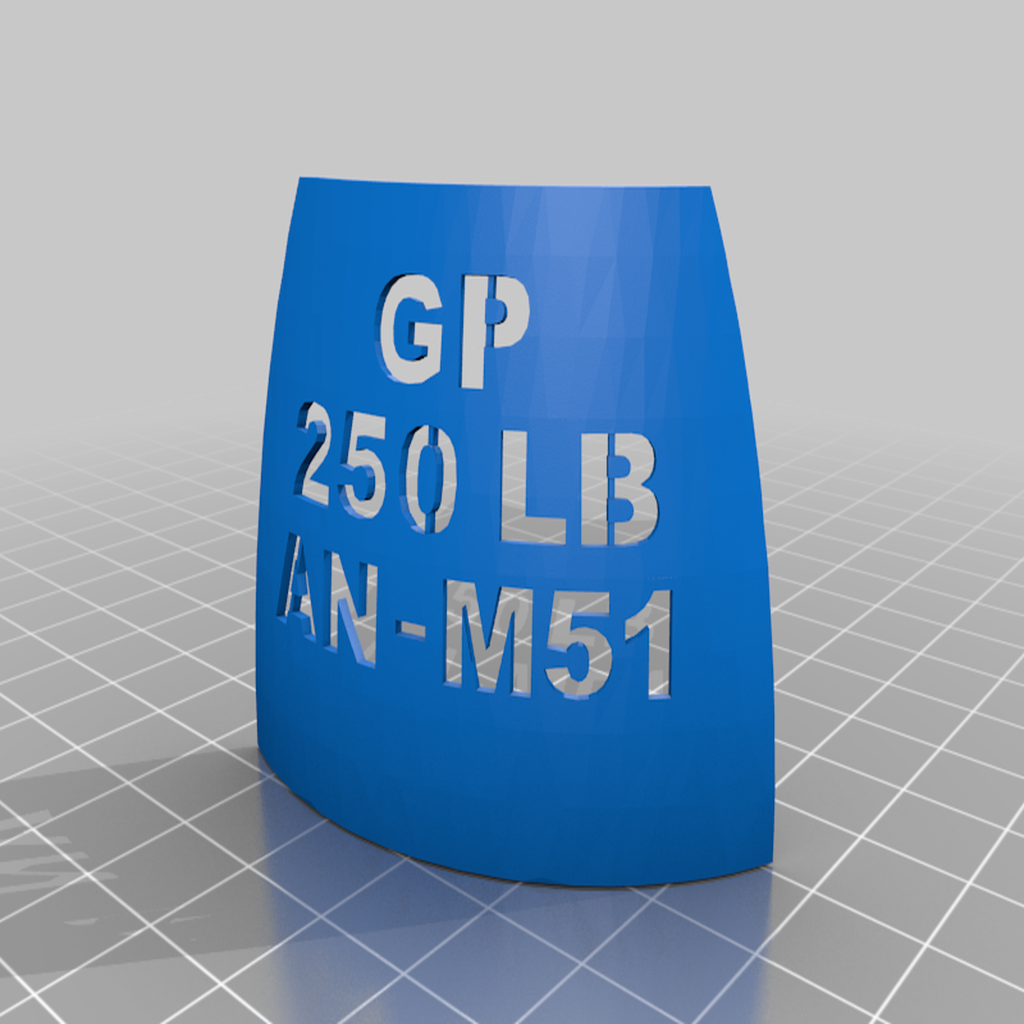

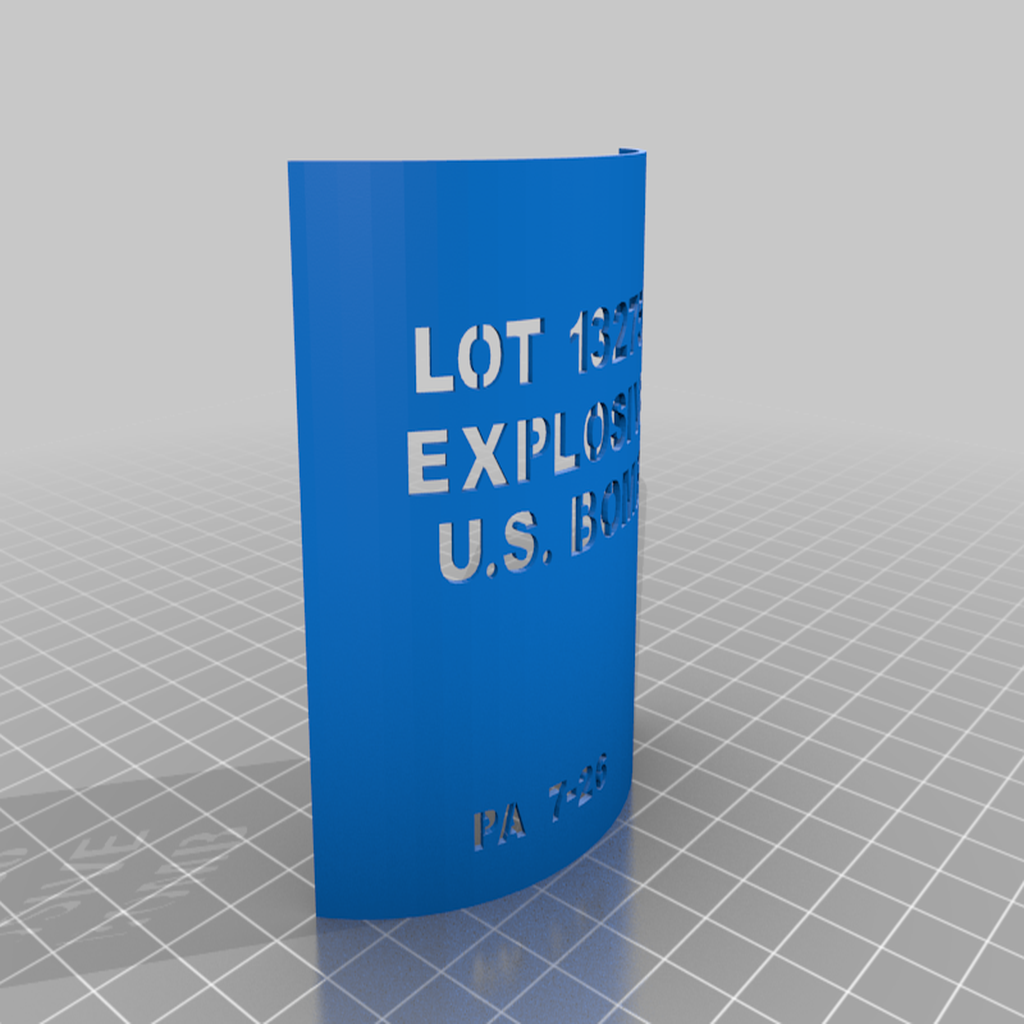

6) If you're really good with an airbrush, you should be able to re-create the "sprayed through a stencil" effect for the lettering on the bomb. Or you could print the stencils I've provided and literally spray through them for the same effect. Optionally you can go to the original design and download the decals included there.

I've flown this on an Estes E12-4 and it went perfectly. In my case I didn't need to weight the nose but your mileage may vary there. Do a swing test for stability to be sure.

Here is the (fuzzy) video of my launch...

https://www.youtube.com/watch?v=6Rw_B7iuyM8

Onboard video from another launch (ignore the date, camera's date/time wasn't set)

https://www.youtube.com/watch?v=gt958Wjc7TY

UPDATE: Thingiverse didn't get all the STLs when I first created this thing. I've added the missing ones.

UPDATE AGAIN: DON'T use an elastic shock cord on this. Just use the Kevlar line. I launched it with an E12-4 today and the elastic failed on ejection causing the rocket to plummet nose first to the ground carrying not only my cheap 808 camera, but a $100 altimeter. Luckily it landed in soft ground (looking like unexploded ordnance) and everything, including the rocket, survived. Considering it reached 450 feet, that's no small miracle. Here's the video, you can clearly see it loose it's main chute.

https://www.youtube.com/watch?v=hWNZXObw-RY

The Bomb Cradle for this is found at https://www.thingiverse.com/thing:4622791

/https://fbi.cults3d.com/uploaders/17181044/illustration-file/9c4b4685-4c1a-49b3-a643-b110f3cc8900/20191016_210905.jpg)