3D model description

https://youtu.be/jm5xXJCzGQw

"Marblevator, Christmas Tree" is a Christmas Tree themed marble run.

Standing 230mm tall with a 10 degree taper from bottom to top, this contemporary styled model consists of five unique (six total) 3D printed components: the base, motor gear, guide, star halves (two required) and track.

The model implements my previously published "inverse auger" design to lift 8mm ball bearings from the end of the track at the base of the tree to the start of the track at the top of the tree. Once on the track, the ball bearings spiral down the tree to the end of the track to repeat the journey.

This model will be on our Christmas Table to entertain our kids and grandkids!

Designed using Autodesk Fusion 360, sliced using Ultimaker Cura 4.11.0 Engineering Profile, and 3D printed in PLA on Ultimaker S5s.

3D printing settings

Parts.

I acquired the following parts:

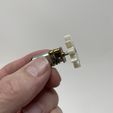

• One N20 6VDC 60RPM gear motor.

• One 6VDC power supply with a male coaxial connector.

• One coaxial female connector compatible with the power supply connector that fits in a 9mm hole.

• Twelve 8mm ball bearings.

I 3D printed two of "Star.stl" and one each of the remaining components at .15mm layer height, 20% infill and no supports using the Ultimaker Cura 4.11.0 "Engineering Profile".

Assembly and Operation.

Prior to assembly, I test fitted and trimmed, filed, drilled, sanded, etc. all parts as necessary for smooth movement of moving surfaces, and tight fit for non moving surfaces. Depending on your slicer, printer, printer settings and the colors you chose, more or less trimming, filing, drilling and/or sanding may be required to successfully recreate this model. I carefully filed all edges that contacted the build plate to make absolutely certain that all build plate "ooze" is removed and that all edges are smooth using small jewelers files and plenty of patience. Using the track and guide, I then manually tested the marble lifting mechanism and carefully filed and sanded the exit and entry track areas as required for smooth entry and exit operation.

To assemble the model, I performed the following steps:

• Soldered a 100mm length of red wire to the gear motor "+" terminal.

• Soldered a 100mm length of black wire to the gear motor "-" terminal.

• Pressed "Gear, Motor.stl" onto the gear motor shaft.

• Pressed the gear motor assembly into "Track.stl".

• Soldered the motor red wire to the coaxial connector "Tip" terminal.

• Soldered the motor black wire to the coaxial connector "Ring" terminal.

• Applied power to the motor to insure the motor ran counter clockwise when viewed from the motor gear end.

• Removed power and slid "Guide.stl" into the track assembly.

Secured the coaxial connector to "Base.stl" using the included nut.

• Aligned the base assembly with the track assembly, then pressed the base assembly into the track assembly making certain the wires remained clear of the gears (a small dot of thick cyanoacrylate glue may be required to hold the base and track together).

• Using a small dot of thick cyanoacrylate glue, glued the two "Star.stl" halves together.

• Pressed the star onto the top of the guide (a small dot of thick cyanoacrylate glue may be required to hold the star in place).

• Plugged the power supply into the coaxial connector.

Once assembly was complete, I plugged the power supply into the mains and added twelve marbles, one by one to the top of the track.

And that is how I 3D printed and assembled "Marblevator Christmas Tree".

I hope you enjoyed it!

/https://fbi.cults3d.com/uploaders/13550170/illustration-file/3c9a04dd-2811-4c45-9e25-6ae289803647/Image000a.jpg)