this is to polish the rifling on my old .577 rifle

Honer the inventor (so my big gripe is:

IS intelectual slavery

since patent infringment changed from a criminal offence to a civial ofence in 1976 patents are not worthy of the name. and inventors are the slaves to corporations !! Isambard Kingdome Brunell would be so happy today!!

So I all I ask is £50.00 for a coppy of my invention, and ask that you honor the inventor and pay the feryman. the rest in comittion.

Getting back to what you are realy here for::

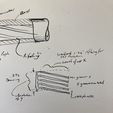

You can do conventional rifeling.

progresive rifeling

all profiles of rifeling from standard land and grove to the fancey H&K styles.

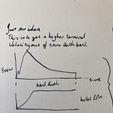

Now here is somthing funky.

as you can do variable pitch (twist rate) and you can do vriable width of lands , you can with this do somthing that is very unusual and that is you can reve the bullet up to the rpm you want in the first few inches of barel whils the presure is high and then jut let it acelelrat the resto of the barile,, this gives higer velovity for the same bulet and powder. so that is prety cool and worth the money.

this is just the initial upload

will be putting up pictures and parts list

as well as links to the Arduino code

firmware and CNC

And the g code for the rifling for this Enfield musketoon

So basically, if you have a barrel that needs to be rifled or re-rifled you can now build one of these machines.

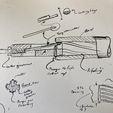

the machine consists of a few parts:

software:

1:cad ( you can draw your own rifleling profile or you can use the ones I have already done or you can PM me and we can make a profile that will work for you.) this this then gives you a .STL file

2: next you need a firm ware. This gets loaded on the arduino, then the perimeters are set

3. You need a man machine interface for your computer USG

Hardware, here again there are two lots

1: parts that need to be printed, you can print yourself or I can send you the parts.

2: Parts you have to by . Arduino, CNC shield, drivers, nema 17 motors two of , 20mm rails, noe the lenth pf your barel and one twice the lenth of your barel, nuts and bolts and t- nuts

Then you put it all together.

Load the .STL file into the machine and you can cut the rifling you want.

Or you can just buy the entire machine from me?

The best part is the requires no coolant so no mess so this can be done on the dining room table.

https://winder.github.io/ugs_website/

How it works:

it thinks it is a cnc machine:

The x axis is the rotation of the cutter to give the twist

the Y is the stroke of the cutter in and out the barley.

so this is a two cnc axis router ( well it thinks it is )

but it is infact a rifling machine.

but a rather special machine in that we can now change every aspect of the rifling variable twist rate, variable width variable depth various profiles to name but a few.

So I set up an Arduino board with a cnc shield (a board that fits on the Arduino to mount all the encoder motor drivers.)

CNC Shield V3.0 Expansion Board Kit + UNO R3

with power supply.

https://ooznest.co.uk/product/350w-power-supply/

actually I think I might just do a video on YouTube.

/https://fbi.cults3d.com/uploaders/14780780/illustration-file/44dbcc4a-318f-4e8a-bd11-982c69b290e6/5ED50EDE-62B2-4661-8A6B-FF5CD4E94798_1_105_c.jpeg)