Only available on Cults3D!

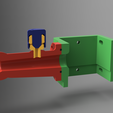

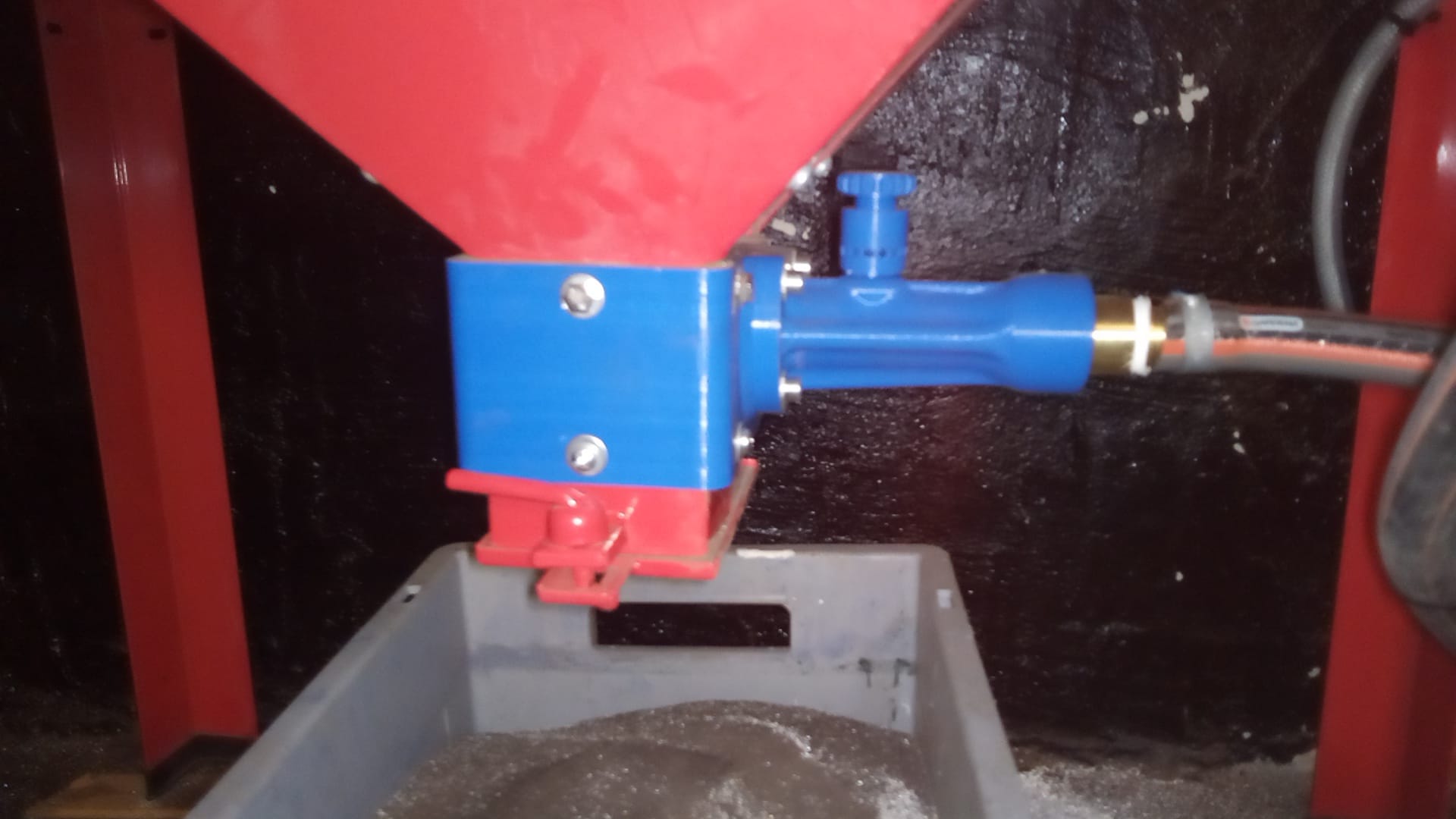

A metering valve including air mixing valve for all 220l China sandblasting booths. These booths are sold under different brands, in terms of design they are all the same.

To our knowledge, the best known resellers are Powerplustools and Harbor Freight.

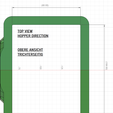

Dimensioned pictures of the top and bottom of the adapter for the dump door can be found in the gallery.

From these, you can see if the parts will fit on your sandblasting cabinet.

If your cabin has different dimensions at this point, just write to us!

We are sure to find a solution.

Matching here is our supply air regulator:

https://cults3d.com/en/3d-model/tool/lufteinlass-regelbar-fuer-220l-sandstrahlkabinen

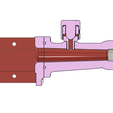

The supplied suction pipe, which is only inserted into the blasting medium is completely unsuitable, as it is constantly clogged. Even the conversion to a pipe-in-pipe system does not really make the work more trouble-free.

Professional sandblasting systems work with a metering valve with integrated air mixing valve that sucks in the medium directly at the bottom of the collection hopper. This way, there is no vacuum in the suction area and you can blast continuously until the compressor glows once it is properly adjusted.

Here is a very good video which explains how to tune this and any other valve of this design to your system:

https://www.youtube.com/watch?v=rlff1yMjA-k

(We have nothing to do with this channel).

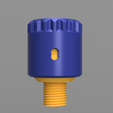

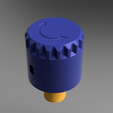

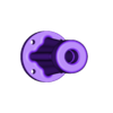

The air mixing valve, which is screwed on and can also be fully pressurized, is used to regulate the air supply to the suction line and thus set the maximum amount of blasting material that is sucked through the hose.

The pictures still show the old version of the air valve.

The new version has a protective screen for the inlet ports, so that the sand does not shoot in all directions when you backwash the hose. (Hold the nozzle closed and press briefly).

This is necessary when there is a lot of dirt and debris in the old abrasive that can impede the flow of abrasive.

Other metering valves require a 1 1/4 inch hole in the sand drain valve.

This design maintains the function of the flap and does not require drilling.

Material needed for assembly:

4x Melt-in threaded sleeves M6x13

4x Screw M6x20 (the screw must not protrude inside, otherwise the sheet metal of the funnel will be in the way! Head does not matter)

12x screw M5x15 (a little longer is also OK, head does not matter).

12x nut M5

24x washer M5

1x O-ring 40x3.5 or a suitable flat rubber gasket

Teflon sealing tape

Silicone

Tap 1/4 inch

Tap 1/2 inch

We believe the assembly is self-explanatory based on the pictures.

If you still have problems with it, just write to us!

The silicone is meant to seal the bottom joint, between the drain valve and the adapter. Here the sand will trickle out a little.

The Teflon tape is used on the 1/4inch thread of the air valve and the 1/2inch thread of the suction hose connector, which are to be cut by yourself.

For a complete dispensing valve, you come including filament and material to about 20€.

For a homemade valve from hardware store parts you spend at least 50€, as well as for cast aluminum dispensing valves.

PRIVATE LICENSE

It is forbidden to resell the files, as well as to sell the printed parts.

/https://fbi.cults3d.com/uploaders/20764544/illustration-file/6e5bcbf3-c398-408e-96d8-364c49ca6413/AnsaugventilSchnittSTEP-schnitt.png)