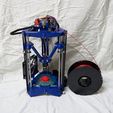

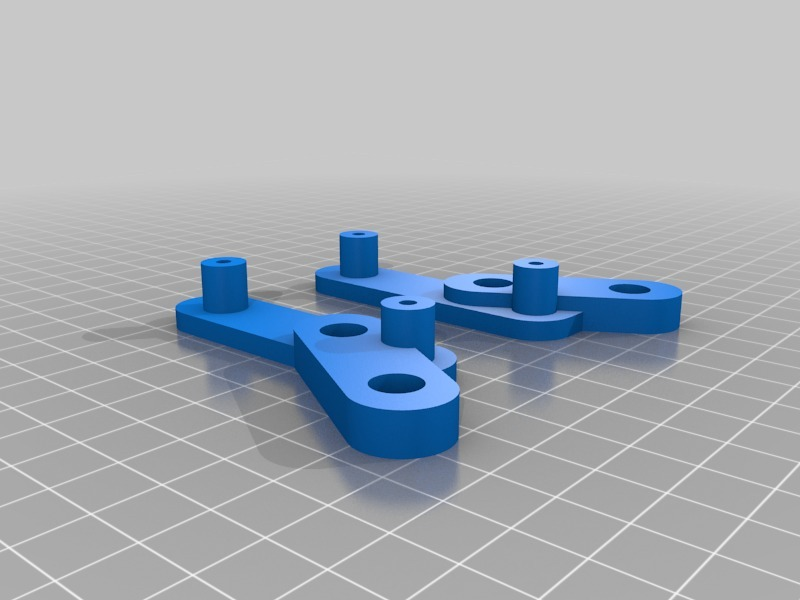

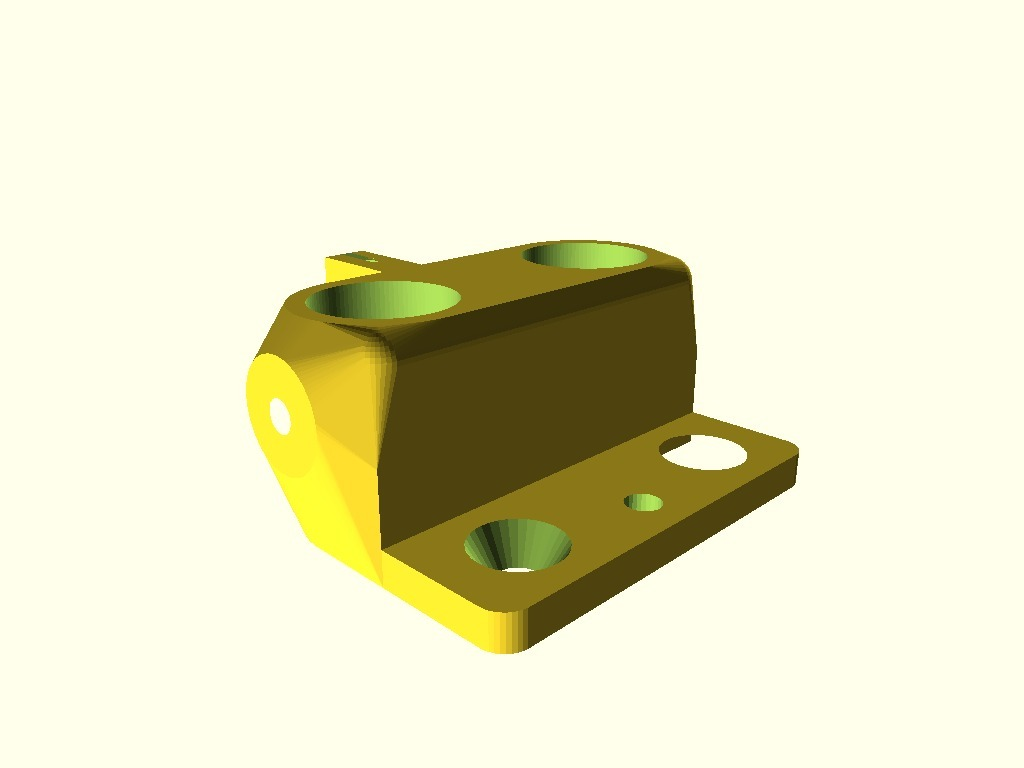

CloverPlus v2

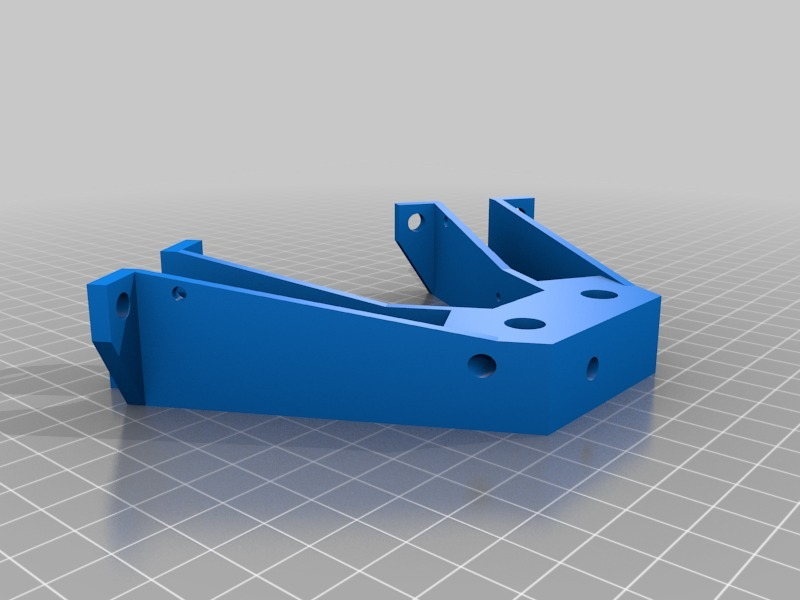

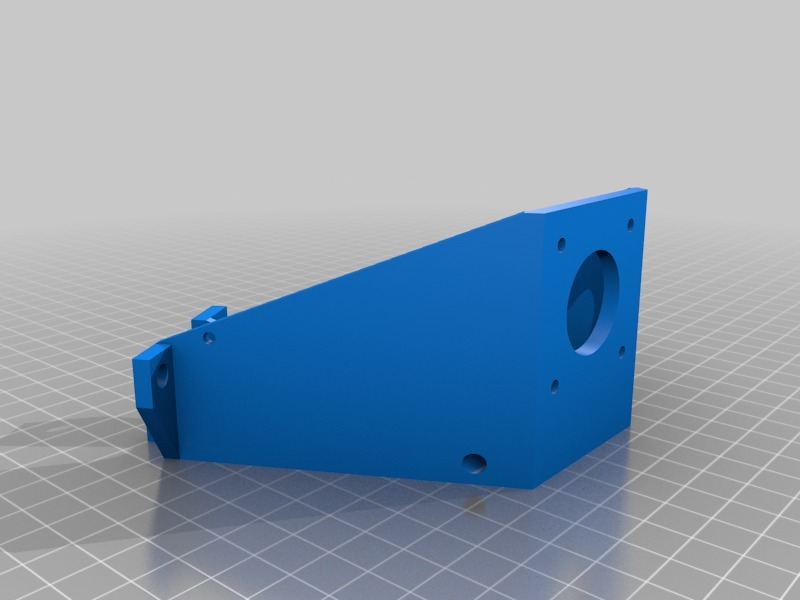

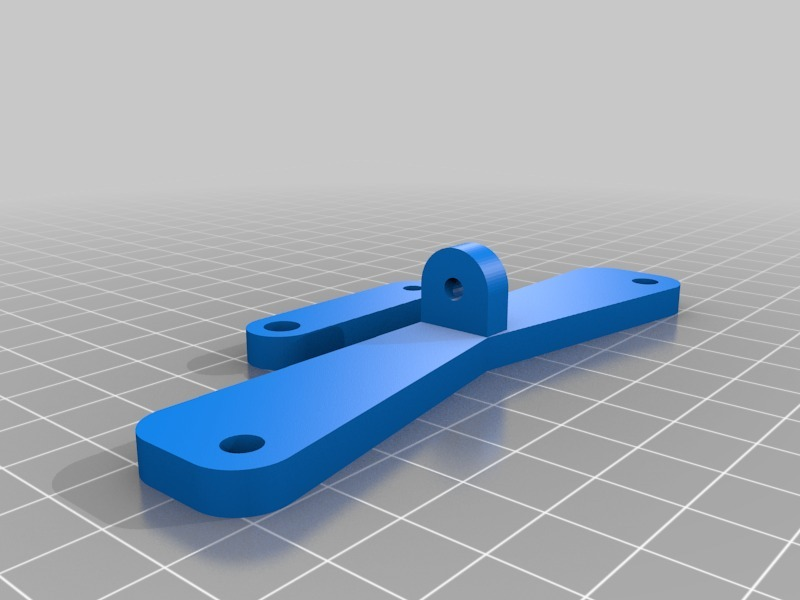

First and foremost this is a remix of the Reprap Clover by xAuSolarisx (thank you! I had a fantastic time building this) and contains the Compact Bowden Extruder by schlotzz (also thank you! I've used your design on multiple printers now).

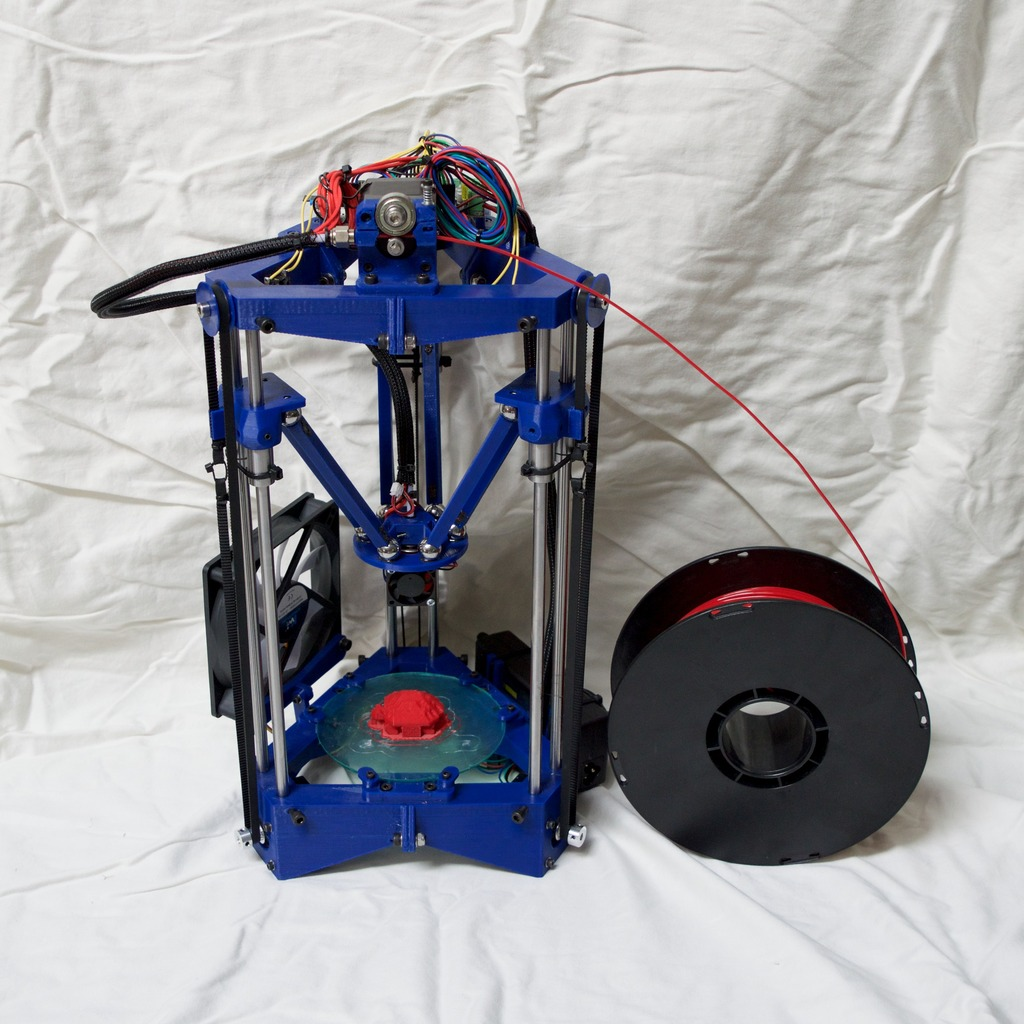

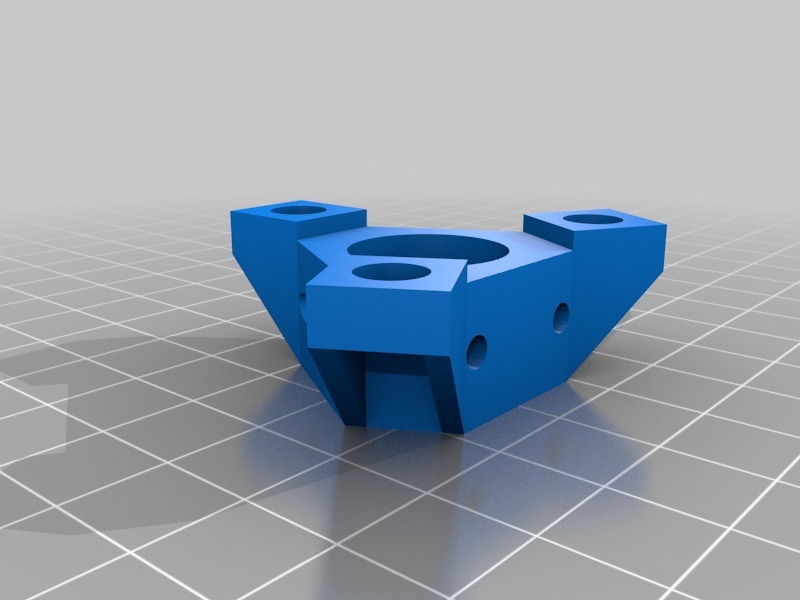

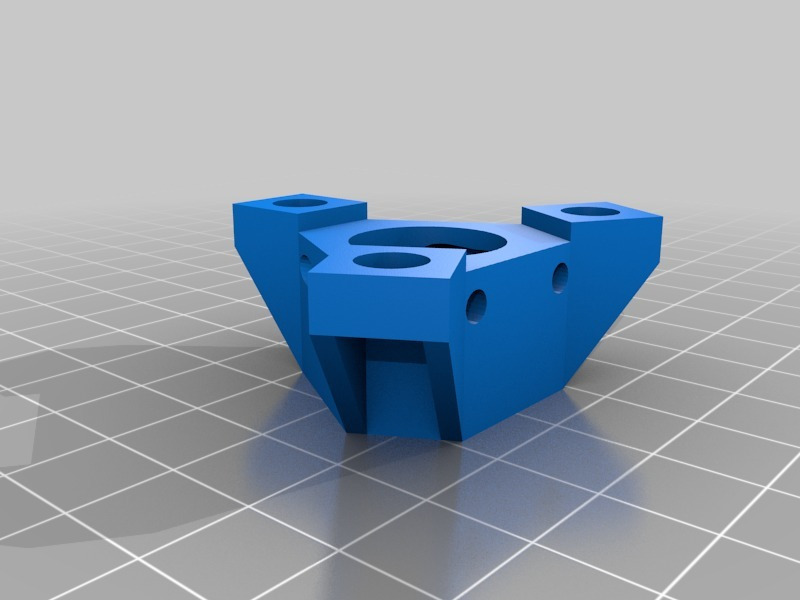

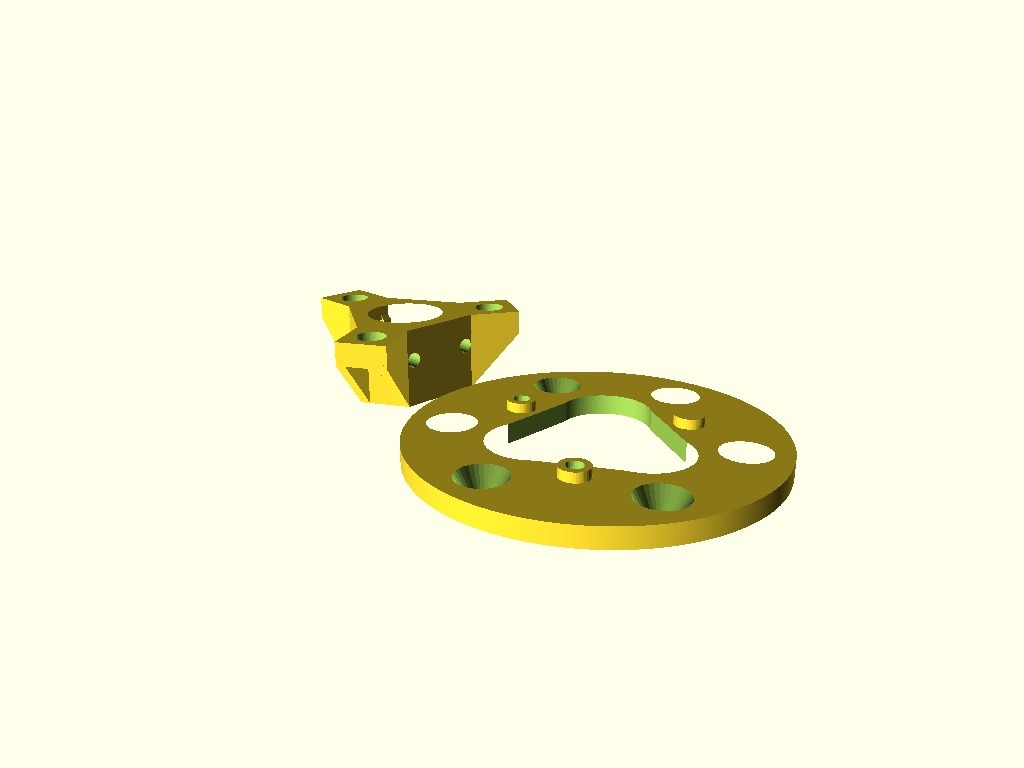

The CloverPlus is a small, mostly-printable 3D printer with delta kinematics.

Please see the next iteration of this design, the CloverPlus v3 3D Printer:

http://www.thingiverse.com/thing:1781851

Printable Diameter: 100mm+

Printable Height: 105mm+

With 105mm arms it's probably possible to print slightly beyond the 100mm diameter.

Printable height is about 105mm with an E3D hot end and 300mm rods, more with longer rods and / or a shorter hot end, like a j-head.

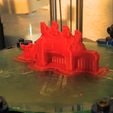

Mechanically the CloverPlus v2 can easily print at 100mm/s and move at 150mm/s or so, though this is highly hot-end- and controller- dependent.

Printing video: https://youtu.be/dCSyj_GUx3U

OctoPrint Timelapse: https://youtu.be/2u4MGgkmk7k

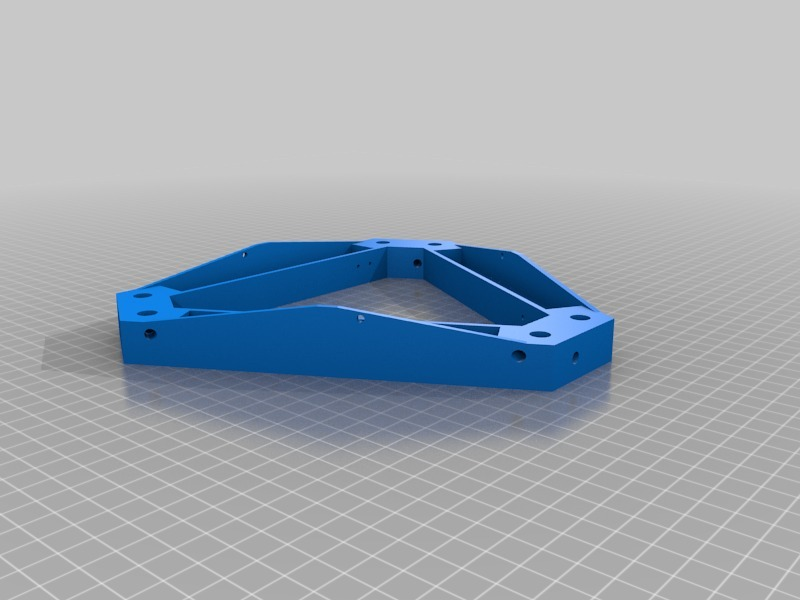

Calculated v2 delta variables

rod center to plate center = 100.429

carriage to ball center = 18.7

effector ball center to nozzle center = 14

"delta radius" = 58.729

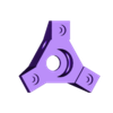

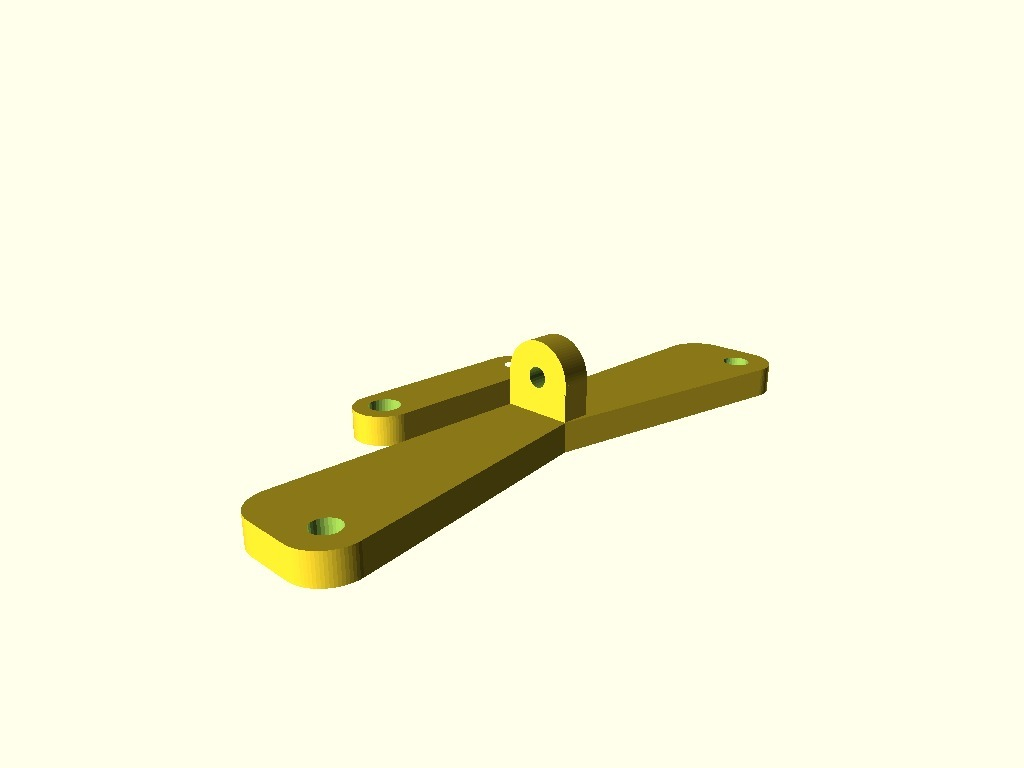

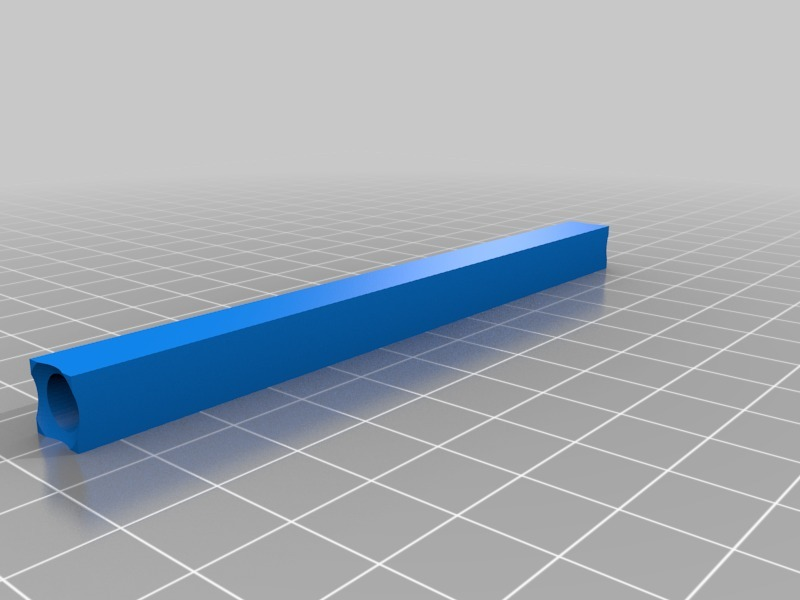

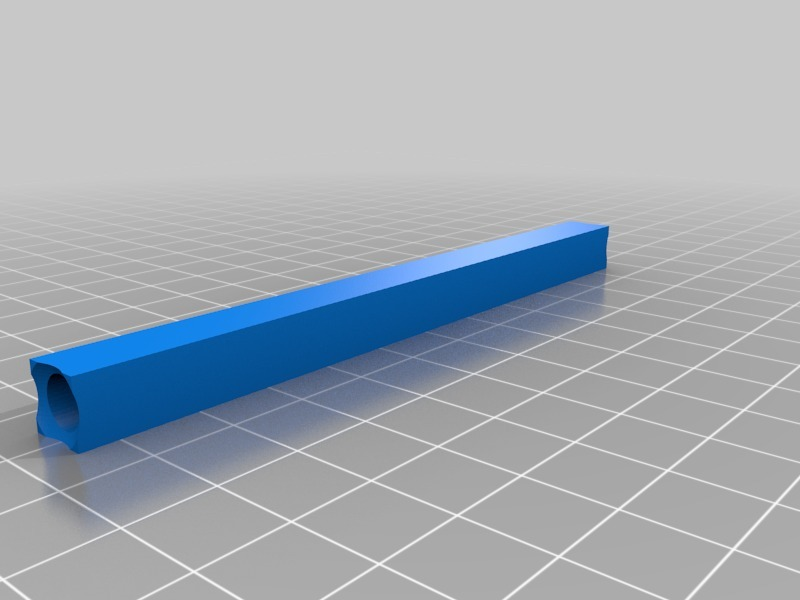

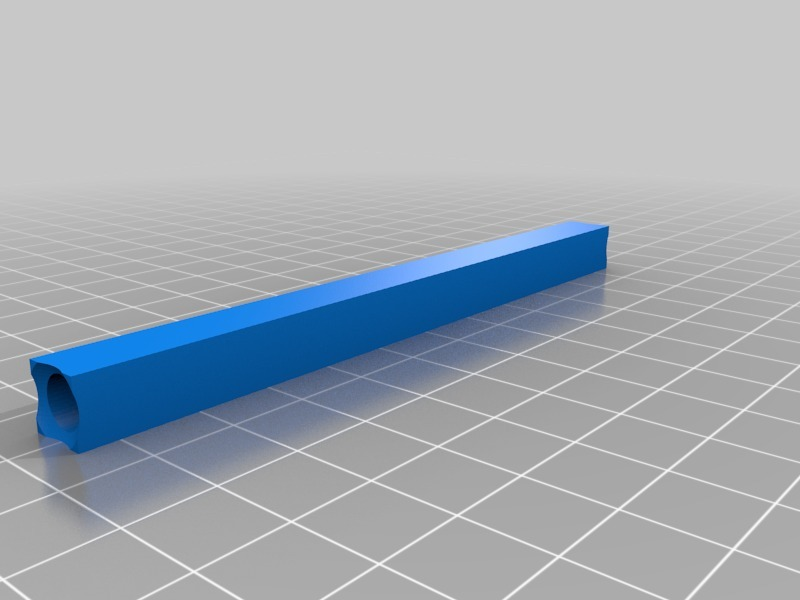

arm length = (105mm arm length + 7.5mm * 2 to center of ball joint on each end)

"diagonal rod length" = 120 for 105mm arms

"diagonal rod length" = 115 for 100mm arms

Recent Updates

Updated 9/21/2016

* CloverPlus v3 3D Printer has been posted!

http://www.thingiverse.com/thing:1781851

Source

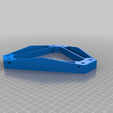

OpenSCAD source is posted for all parts except the Compact Bowden Extruder; see the Remixed Source Files for that.

Build Details

See the attached CloverPlus_BOM.xlsx for part details. Let me know if something is missing or something doesn't make sense.

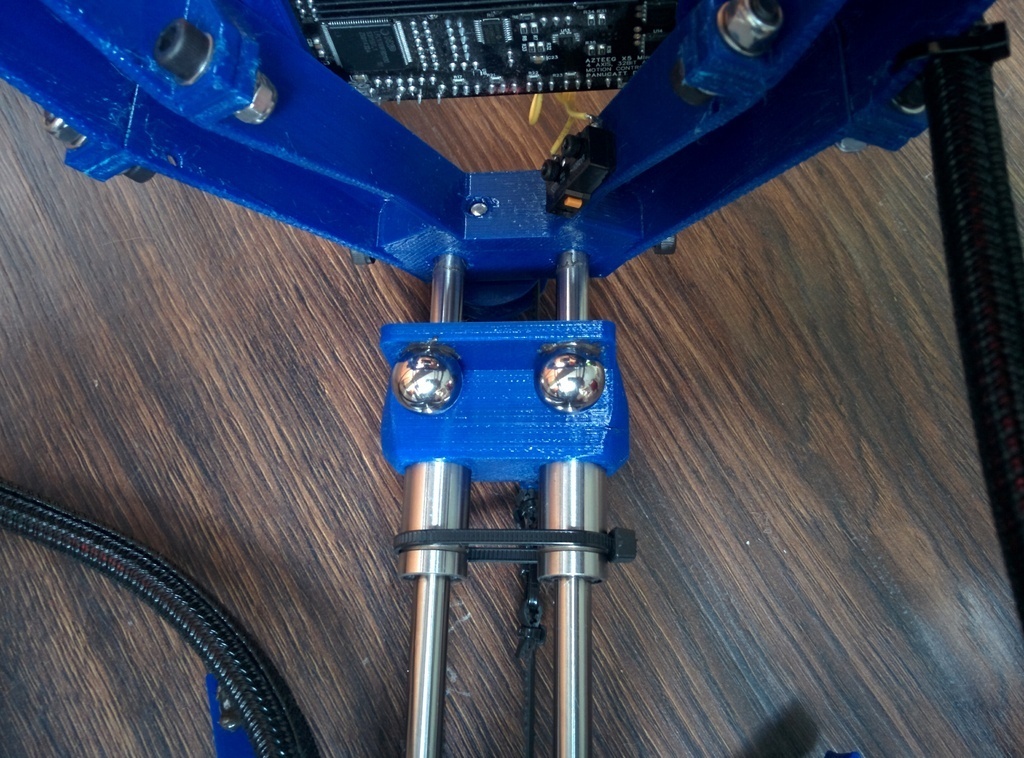

I used 300mm and 330mm Misumi P/SFJ8 rods and JB Kwikweld epoxy to secure the magnets and steel balls (after roughing with 120 grit sandpaper).

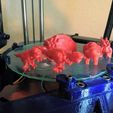

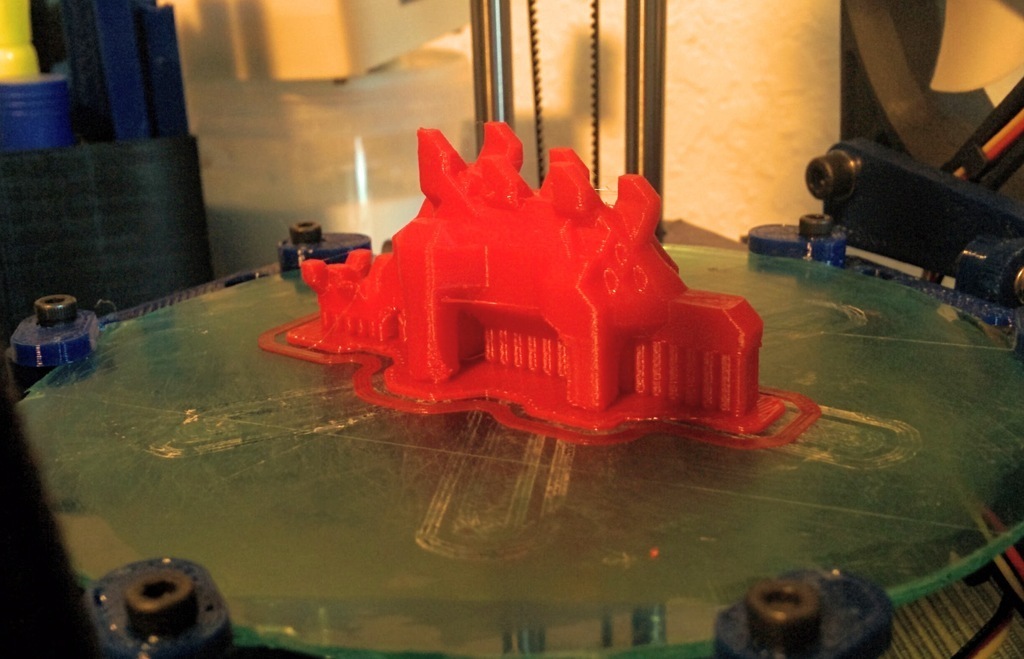

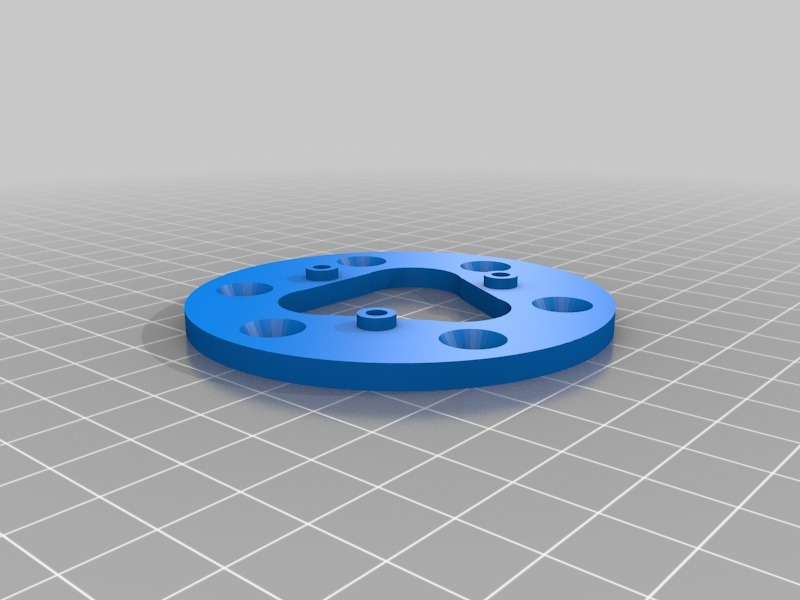

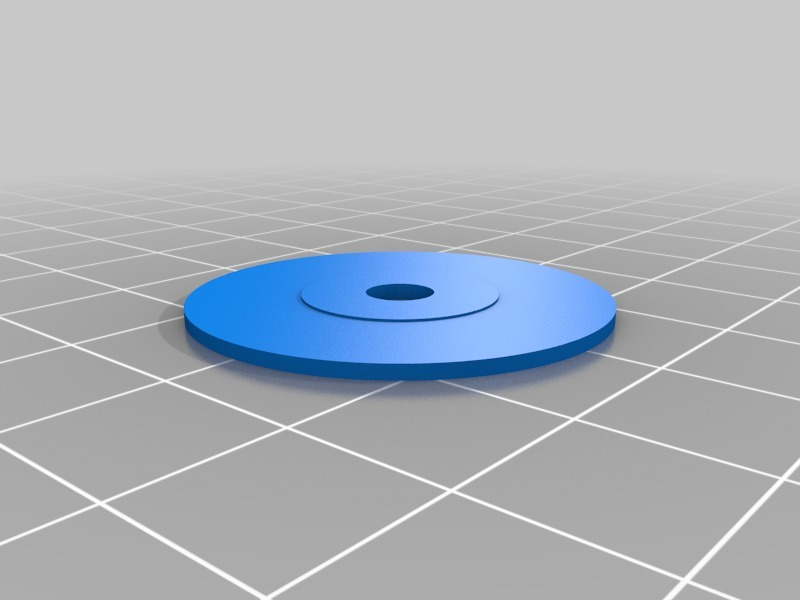

The bed glass in the photo is 120mm in diameter and about 2mm thick, though 110mm would also work. I cut it with a circle cutter out of a sheet of (I believe) 3/32" glass from Lowes. Print volume is about 105mm high (300mm rods and E3D hot end) and 100mm in diameter. I recommend using glue stick (Elmers purple or extreme) on PET or Kapton tape for printing PETG and PLA without a heated bed. You can apply it straight to the glass, but this will inevitably result in scratched glass.

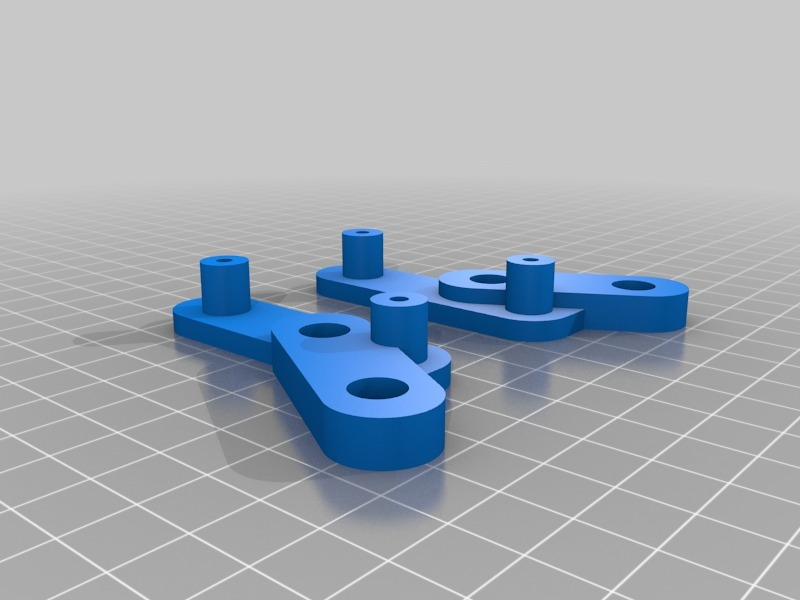

Open Issues / Build Tips

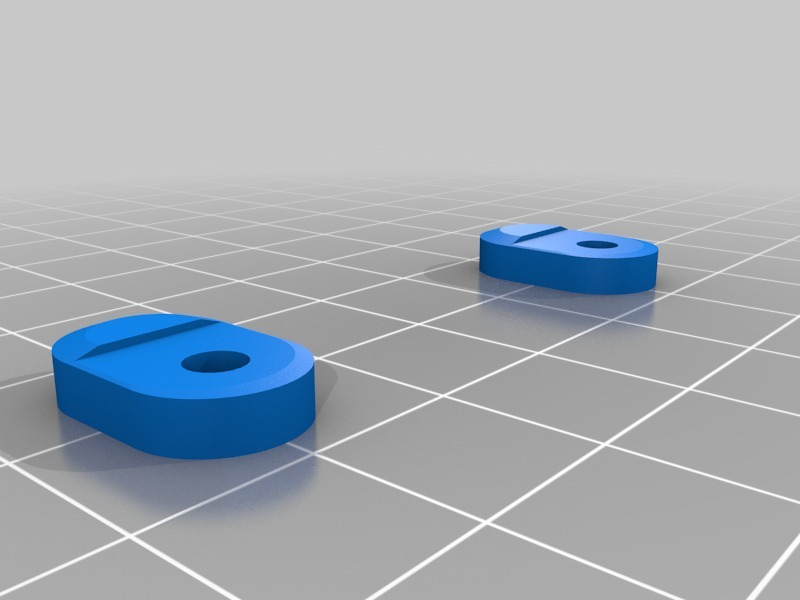

I recommend 10mm N50 magnets as these are strong enough to be forgiving of a slightly longer magnet gap than usual. There are arms with many different magnet slots posted - measure your magnets with calipers and if there isn't a .stl to match, tweak the .scad with the measured size and generate a custom arm .stl. The 0.2mm gap I have in the .scad has tested good with multiple magnet combinations.

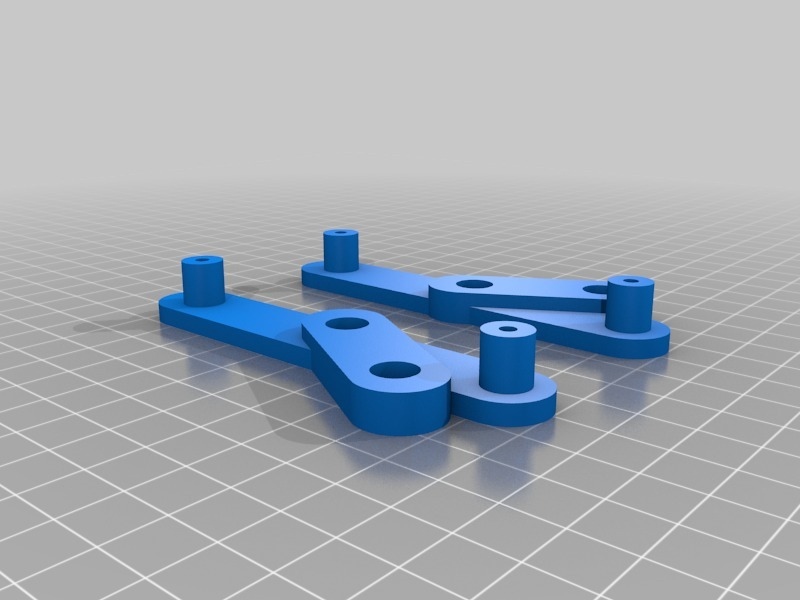

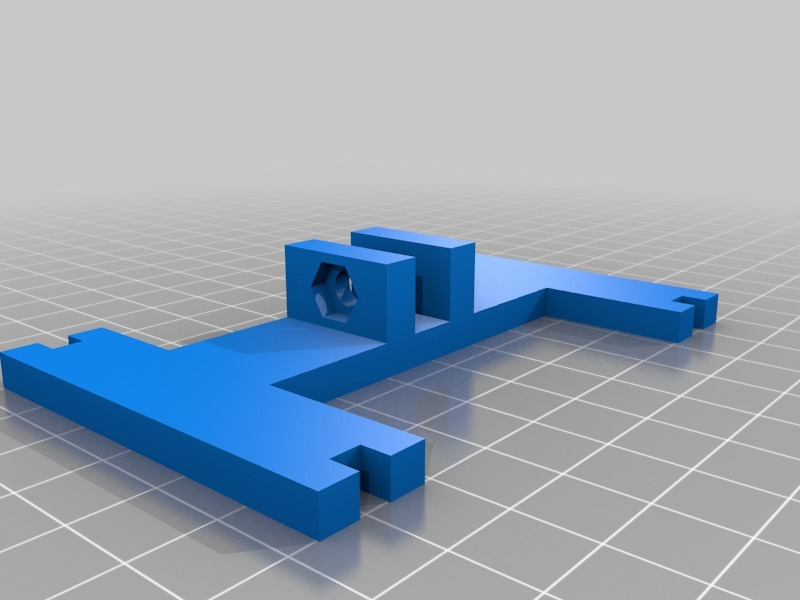

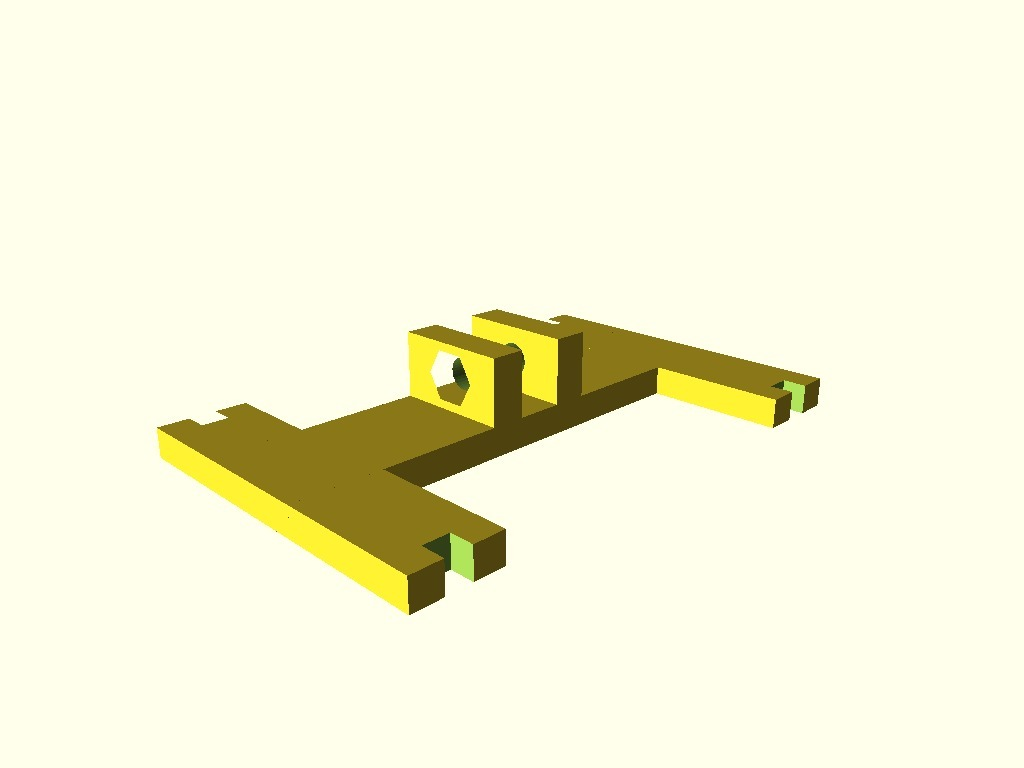

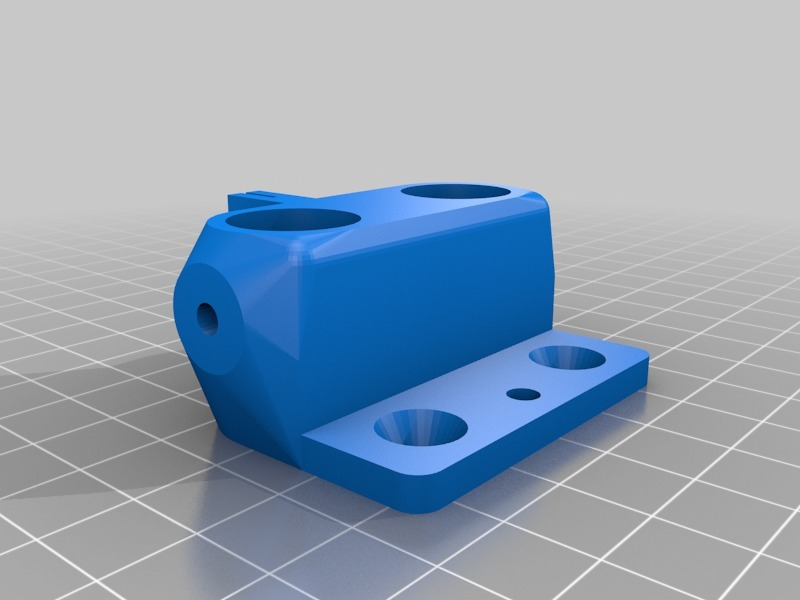

Use 8mm x 15mm x 45mm LM8LUU bearings instead of the shorter LM8UU bearings.

The rod holes in the frame pieces may need to be tweaked for a good fit depending on how accurate your printer is at printing holes. After calibrating my extrusion width I have the rod holes sized at 8.2mm with spacing (center to center) of 30.1mm (carriage spacing is 30mm) to allow for the screw clamps to push them inward and close the spacing to about 30mm. Change the rod_extra and rod_spacing variables in cloverplus_topbottomv2.scad to suit your printer.

Rod sizing can be anything in the 300mm range (I've used 300 and 330). You can probably even get away with 400mm as the frame is pretty stiff, but I haven't gone that far.

Bowden tube sizing needs to be generous to avoid placing too much stress on the effector which could pop the mag arms.

Sand both the plastic and the steel balls / magnets with 120 - 300 grit sandpaper and then clean with alcohol before gluing.

Make sure the magnets slide all the way back into the arm recesses before gluing via the slots. Test the spacing to ensure the ball does not contact the magnet. After gluing, trim / sand / file the arm to ball contact points as necessary to ensure wiggle-free operation.

I use cork spacers for the motors to reduce vibration and provide some heat insulation. PETG's glass temp is about 85C, but PLA's is much lower at about 65C, so watch your motor temps if you use PLA.

0.4mm hot end nozzle size or smaller is recommended due to the build volume

Firmware setting delta variables are at the top. I highly recommend this delta calibration tool: http://escher3d.com/pages/wizards/wizarddelta.php

I recommend a 32-bit Smoothieware or Reprap Firmware based controller board. An 8-bit arduino-based board running Marlin will work, but it will have trouble running at 60mms or faster - prints will be rough and the steppers will stutter. Repetier firmware on 8-bit machines is reportedly better suited to delta printers than Marlin, but as I was not able to get my Osoyoo board to correctly stream g-code using Repetier without utterly failing, I can't personally recommend it.

For extra pizzazz (higher resolution) with a 32-bit controller, use 0.9degree / step steppers. I used 1.8d/step motors on my CloverPlus builds, but 0.9d steppers don't cost much more and are a good fit for small, highly-detailed prints.

Acceleration of 1500mm/s^2 and Junction Deviation of 0.05 (Smoothieware) or Jerk of 10 or lower (Marlin) is a good place to start.

If you have any questions, please ask in the comments! :)

/https://fbi.cults3d.com/uploaders/30568940/illustration-file/721f571b-8d28-4333-a259-da1e683a8af5/DSC_1525_1.png)