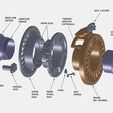

Here’s my take on a Hubless Fly Reel. I love the look of hubless reels such as the LUNAR AC2, LOOP and others and wanted to try my hand at this. Design goals included;

• no additional hardware required to assemble the reel,

• a bi-directional leaf spring and pawl clicker,

• an auxiliary clicker (this was my first attempt at a clicker but decided to leave it in),

• an adjustable drag system.

I was mostly successful in avoiding glue but have resigned myself to krazy gluing the spool halves together. The entire reel will assemble and work without glue but line pressure in the spool forces the spool halves apart creating unintentional drag against the frame and keyed drag hub. I now also glue the handle post to the outer spool. Over time the interference fit between the outer spool and handle post relaxes and can pop loose. The overall dimensions of this reel are 88mm OD x 33mm wide. The spool dimensions (line storage) are 53mm ID 77mm OD x 21mm wide. These dimension are similar to my Supreme QRS 2/3 4/5 fly reel. All the gray parts in the photos use the Prusa PLA filament that shipped with my printer. The white parts are Overture PETG. Not sure how PLA will hold up on a hot summer day but wanted to print this in the two colors I have right now.

Before you start printing, ensure you select the correct frame. I have included both left hand and right hand frame STL files. The pictures and model views all show the right hand frame. Most of the parts print without supports except for the inside half of the spool, handle post and reel frame that require “supports on build plate only”. I also use 100% infill for all parts.

Assembly Notes:

1) Handle Post (PETG):

The handle post snaps into any two of the openings in the outer spool half. It is a very tight interference fit but once you snap it in place, it is very solid. Note I've noticed the interference fit will relax over time so I now recommend using Krazy glue on this connection. Gently work this piece into place with pliers or maybe a deep socket over the post to tap or press it into the spool openings. I used PETG for the post and outer spool for flexibility and strength.

I haven’t tried this fit with PLA parts. You may want to trim or sand the raise edge of the bosses on the handle post and use super glue instead.

2) Handle (PLA):

After the post is in place, push the handle over the post. Place the outer spool flange and handle post on a flat surface before pushing the handle into position. It should pop into place and spin freely once installed.

3) Spool Halves (PETG):

Use Krazy glue or another super glue to bond the two spool halves together.

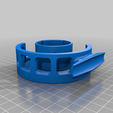

4) Leaf Springs and Pawls (PETG):

Install one or more sets of leaf springs and pawls on the inside end of the assembled spool. Only a single leaf spring and pawl is required but six pawl stations are available. You can install more than one spring and pawl set if you wish. You can also disable any installed pawl by turning it 90 degrees so that the spring holds the pawl away from the gear located in the reel frame (see pictures). Note: Install the pawl first and be sure is spins freely on its post before installing the leaf spring (try removing and installing the pawl multiple times and flipping it over each time so that the pawl is very loose and almost to the point of falling off - IT MUST SPIN FREELY ON ITS POST). I use a small amount of the lube that came with my printer on the pawl, spring and gear (in the frame). The lube helps these items last longer and reduces the noise of the pawl clicker.

Reel Frame (PLA):

With at least one active pawl, install the spool onto the hollow hub of the reel frame and ensure the outside surface of the spool is flush with the end of the hollow hub and that the pawl(s) are seated in the gear. You may need to rotate the spool slightly to get the pawl(s) to seat. Once seated you should hear the pawl clicking when the spool is turned.

5) Drag Hubs (PLA):

Prior to installing the Drag Hubs lubricate the threads with Vaseline or Prusa printer lube and ensure the hubs thread together smoothly. You may need to work the threads back and forth 20 or 30 times to get them to wear into each other and operate smoothly. Install the keyed drag hub in the keyed end of the hollow hub. Insert the ribbed hub from the other side and tighten as desired to adjust the drag.

Design note: The keyed drag hub rubs on the outer spool and is keyed to the hollow hub to prevent it from spinning. This prevents the keyed drag hub from tightening or loosening as the spool is turned. This allows single-handed drag adjustment with the ribbed drag hub on the other side of the reel. The ribbed drag hub draws the keyed hub in and out to adjust the drag.

6) Load up some line and go fishing!

Additional Comments:

I have not experimented with lubrication too much, other than on the drag hub threads and pawl(s) as mentioned above. The PETG spool running on the PLA hub is naturally slippery and spins very freely even with one pawl engaged (drag backed off). I have included 4 slot shaped “grease” grooves in the outside diameter of the hollow hub to hold a little residual lubricant but have not tried this yet.

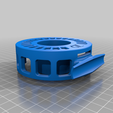

The other supplied “drop-in” clicker (PETG) installs in the slot in the frame beside the reel mount. Squeeze the ends together to engage the clicker in the slot (see pictures). The drop-in clicker is not as satisfying or smooth in operation but it is quieter than the pawl clicker setup. Disengage the pawl(s) (step 4 above) to try this clicker on its own. I have included 4 resistance levels of the drop-in clicker; Light (1 hole), Med Light (2 holes), Med Heavy (3 holes) and Heavy (4 holes) (see picture).

For a very quiet reel just use the drag hubs alone (without the pawls or drop-in clicker).

Finally, thanks to sthone, SublimeLayers and others for sharing their work and providing

inspiration for this design. I welcome any comments, questions or suggestions for improvement.

Also special thanks to Scottmi for the very nice box he designed for this reel. You can find it here: https://www.thingiverse.com/thing:4795672

Enjoy…

Ed

Go to https://zonneveldesign.ca/projects/ to see a brief video of the reel.

/https://fbi.cults3d.com/uploaders/33265753/illustration-file/cd5b0633-af58-4538-9144-ce78b1f2ef26/IMG_2665.jpg)