Copyright Claim

Print Profile(1)

0.2mm layer, 2 walls, 15% infill

1.8 h

1 plate

Boost

21

40

30

1

100

142

Released

Description

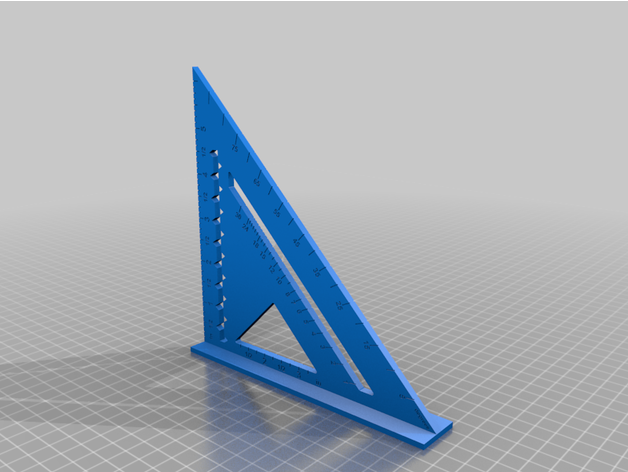

Speed Square 160mm

Slight tweak to original file from Ppep54 in that I added a notch, which the original was missing. This prints great on the x1c and is accurate for square but i haven't tested the angles.

I've printed 2 of these now in PLA (for uk) and they have both been accurate

Prints without support in orientation on import.

Comment & Rating (30)

All

Print Profile

0.2mm layer, 2 walls, 15% infill

just what I needed, excellent print in CF

0

Reply

excellent print, it’s perfect.

I had an existing speed square but it was imperial measurements (which everyone sensible knows is utter nonsense and should be banned) so I wanted a metric one instead. This came out absolutely perfectly square and commercial quality, very happy with it.

0

Reply

great print. feels like it’s accurate. please excuse my lines.

0

Reply

Also Prints on A1 mini in PETG

The designer has replied

0

Reply

thanks for the rating and the comment

0

Reply

Print Profile

0.2mm layer, 2 walls, 15% infill

Great quality! clear and easy to read.

0

Reply

Print Profile

0.2mm layer, 2 walls, 15% infill

Not really the models or the profiles fault, got some ringing higher on the print. A fact of life with tall narrow prints. Still works well and is surprisingly accurate.

0

Reply

Print Profile

0.2mm layer, 2 walls, 15% infill

perfect

0

Reply

Print Profile

0.2mm layer, 2 walls, 15% infill

Printed great! Looks store bought.

0

Reply

Print Profile

0.2mm layer, 2 walls, 15% infill

Excellent details

0

Reply

Print Profile

0.2mm layer, 2 walls, 15% infill

Bed Adhesion Issue:Could really use a brim

The designer has replied

0

Reply

thanks for the feedback - I’ve printed 2 or 3 of these on pei plate on pla without brim on the x1c. what printer /bed /filament did you use?

0

Reply

The user shared this model, but is not the original creator of it.

License

This work is licensed under a

Creative Commons Attribution-Noncommercial