Suspended Baby Raptor Incubator LED Lamp

Suspended Baby Raptor Incubator LED Lamp

Print Profile(2)

![[A1 mini] 0.2mm layer, 2 walls, 10% infill](https://makerworld.bblmw.com/makerworld/model/US6f7bd0f14475bc/48428468/instance/2024-02-07_937650e58b051.png?image_process=resize,w_100/format,webp)

Description

So i just got myself the LED lamp kit and was looking for a cool lamp shades to print for it.. then i came across someone making a incubator like cylinder with an alien in the middle using resin.. i thought it was a great idea.. and so i design one for myself.. but of cause i want to make a suspended version of it..

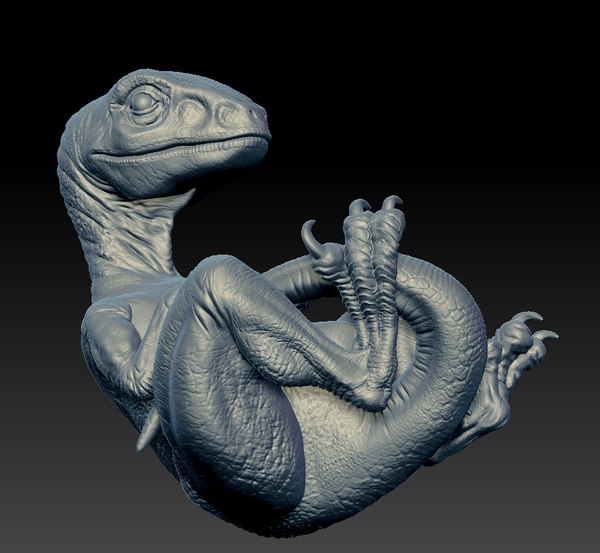

Then i remembered finding a baby raptor model on makerworld.. it was made for resin printing.. so i low-poly the raptor and added the baby raptor blue and turned it into a suspended model.. i had to split the raptor in 2 and added supports to the hanging hands.. legs and tail.. so it might look weird if you look closely..

| :UPDATE: it turns out that the user who shared the raptor model on makerworld is not the owner of the 3D model.. he shared the file without authorization.. The owner reached out to me and told me what the user had done.. the owner of the 3d model is wofle from turbosquid.com.. and he gave me permission to share my remixed version of the raptor as long i dont sell it commercially.. so thank you Mr Wolfe for sponsoring your awesome raptor model for my suspended models.. |

i modelled the incubator using Tinkercad and added the LED kit on the bottom.. so the LED light would shine through the bottom grill of the incubator cylinder and light the suspended baby raptor in the middle..

If you have an AMS i recommend printing some of the incubator parts with transparent filament like i did for the bottom base.. so that the LED would shine through it and make it more cool.. in my opinion..

Assembly is fairly simple.. you just need to be careful when adding the square peg into the raptor's body.. it should fit loosely.. the peg is just used to hold the 2 half of the raptor aligned.. the bottom parts should fit tight.. and the top slightly loose.. the base where you insert the LED kit should fit loosely to the middle base.. so that you can turn your raptor to whichever position you'd like without the wires in the way..

If you're thinking of buying the LED kit.. please do support me by using my affliate link here.. LED LAMP KIT 001 every little things helps me out..

If you would like to support me, you can join me on my buymeacoffee page.. |

By joining me as a supporter.. you'll be able to get behind the scenes information on my current projects as well as future projects.. |

And if you're looking to sell my prints.. you can join my merchant membership tier as low as USD10 a month.. |

Comment & Rating (107)